0102030405

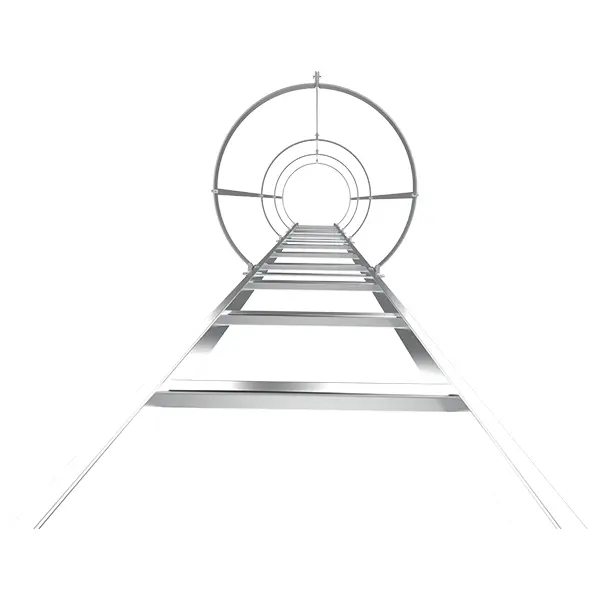

3S Aluminum Alloy Safety Cage

Video

Key Features

High strength

Corrosion resistance

Foldable

Multiple protections

Customizable

Specifications

Model |

TL-HL1, TL-HL2, TL-HL3, TL-HL4 |

Material |

Q235B / SUS304 / SUS316L / 6061 / 5052 |

Surface treatment |

Hot-dip galvanizing / anodizing |

Corrosion resistance |

C4-H 720h |

Cage diameter |

3600 ~ 800mm |

Can be matched with |

3S wire rope fall protection system, rail fall protection system. |

Implementation standards |

GB 5144, GB/T 17888.4, ISO 14122-4, ISO 11660-1 |

Customization |

Customized design and manufacturing can be carried out according to different customer needs. |

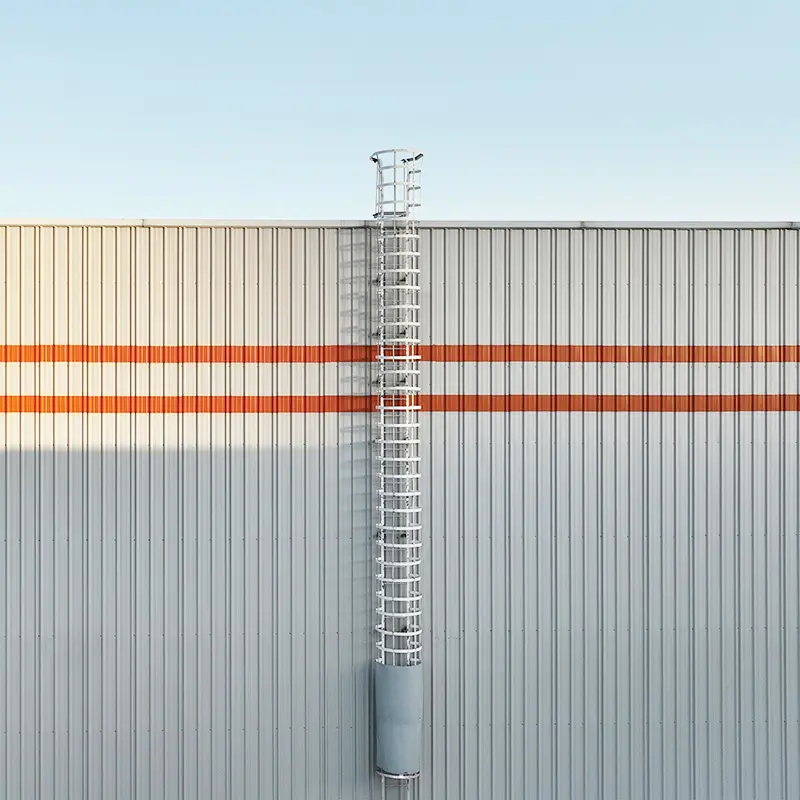

Safety Cage for Climbing Ladders

A safety cage is an essential fall protection system designed to secure personnel ascending vertical ladders, particularly in high-risk industrial environments. Consisting of a tubular steel or aluminum frame with evenly spaced guard rings, it encircles the climbing ladder to prevent falls and provide lateral support. Mandated by the GB5144 safety standard for fixed ladders exceeding 2 meters in height, these cages ensure compliance with occupational safety regulations while enhancing worker confidence during elevation tasks.

The cage’s cylindrical structure typically features a 700–750 mm internal diameter, allowing sufficient space for climbers to maneuver while maintaining close proximity to the ladder. Guard rings spaced at 500–900 mm intervals create a continuous barrier, and the system is often paired with safety hoops or rest platforms for extended climbs. Applications span industries requiring routine vertical access:

● Tower cranes: Protects technicians during mast section inspections or repair work at heights exceeding 20 meters.

● Palletizers/warehouse systems: Safeguards maintenance crews servicing automated stacking equipment.

● Signal/telecommunication towers: Ensures stability for workers adjusting antennas or cabling in windy conditions.

● Power transmission towers: Mitigates risks during grid maintenance on lattice structures.

● Industrial facilities: Secures access to elevated machinery, silos, or rooftop HVAC units.

● Tower cranes: Protects technicians during mast section inspections or repair work at heights exceeding 20 meters.

● Palletizers/warehouse systems: Safeguards maintenance crews servicing automated stacking equipment.

● Signal/telecommunication towers: Ensures stability for workers adjusting antennas or cabling in windy conditions.

● Power transmission towers: Mitigates risks during grid maintenance on lattice structures.

● Industrial facilities: Secures access to elevated machinery, silos, or rooftop HVAC units.

Engineered for durability, safety cages incorporate corrosion-resistant coatings for outdoor use and are often integrated with anti-slip ladder rungs. Advanced designs include anchor points for harness lanyards, creating a redundant fall arrest system. By combining physical barriers with ergonomic design, these cages reduce workplace accidents while enabling efficient vertical mobility in compliance with global safety protocols.

Applications

Ms.Lily International Sales Director

Ms.Lily International Sales Director Join 3S Group

Join 3S Group