Offshore Davit Crane for Offshore Wind Power Operations

Video

product description

Lifting Hook Limit Switch

Equipped with a top limit switch, the hook can smoothly and precisely come to rest at the intended position. The crane also includes a specialized wire rope outlet area and highly adaptable positioning mechanisms, which together minimize wire rope abrasion and thereby extend its service life.

Lowering Limit Switch

The lowering limit switch allows the hook to gently halt once it reaches the desired position. This feature also has the capability to record the position and prevent reverse rolling.

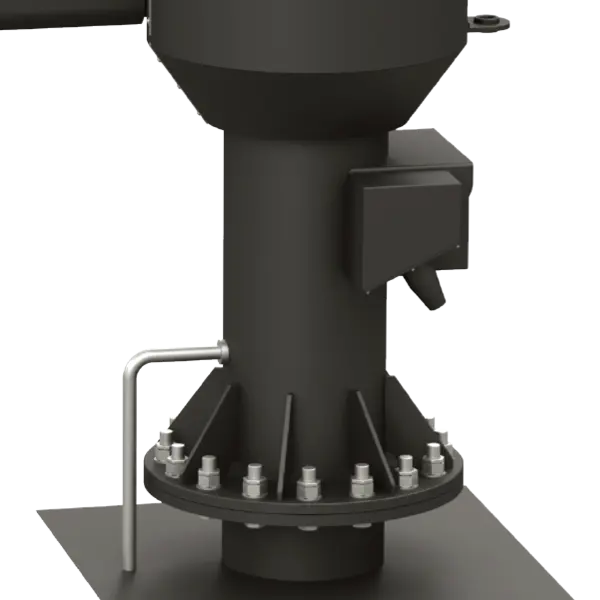

Supporting Column

This component serves as the structural support for the entire equipment and is designed with exceptional strength. It is installed at the base of the outer tower platform, and the column flange can be tailored to meet specific requirements.

Boom Assembly

The design incorporates a hexagon variable cross-section structure that ensures high strength. It is equipped with CX-class corrosion resistance, in accordance with ISO12944-9 standards. Additionally, the slewing radius can be tailored to meet specific needs and requirements.

Drive Unit

The device features a designated wire rope storage position and a power source. Incorporating a winch drum within its design, the gearbox boasts a streamlined and compact structure. The LEBUS rope groove is equipped with a specialized wire rope pressure mechanism and a slack rope limiter mechanism for enhanced functionality.

Slewing Bearing Assembly

The high-precision slewing bearing guarantees a seamless and smooth operation. The self-locking design effectively withstands gusts of up to 70 meters per second, ensuring stability and reliability. Both the electric and manual slewing bearings are designed for ease of use and convenience, providing operators with a straightforward and intuitive experience.

Key Features

Anti-corrosion level CX: Suitable for harsh offshore environments

Customizable safe working load to meet specific needs

Self-locking protection function for enhanced safety

Anti-twisting wire rope to prevent entanglement and wear

Overload protection function to safeguard equipment and operations

Unique wire rope pressure mechanism and slack rope limiter mechanism for optimal performance

Automatic Overload Protection System (AOPS) for immediate response to unsafe condition

Emergency Load Lowering Function (ELL) to ensure safe operation in critical situations

Distributed sealing protection design to prevent moisture and debris intrusion

Specifications

OC-5010 | |

Safe working load |

500 kg—2,000 kg |

Lifting speed |

20 m/min or 36 m/min |

Slewing radius |

5 m |

Max. slewing angle |

360° |

Max. lifting height |

30 m |

Wire rope diameter |

φ 11 mm |

Power supply |

400 V/690V |

Rated power |

8 kW |

Service life |

35 years |

Operating temperature |

-20℃ to 45℃ |

Max. wind speed |

18 m/s |

Max. significant wave height |

2 m |

Ms.Lily International Sales Director

Ms.Lily International Sales Director Join 3S Group

Join 3S Group