Leave Your Message

Maintaining a hydropower facility is crucial for optimal performance. A Hydropower Maintenance Platform can streamline this process. It offers real-time monitoring and data analysis. Operators can track equipment health efficiently.

Effective utilization of a Hydropower Maintenance Platform enhances decision-making. Timely maintenance reduces downtime and prevents costly repairs. However, users often overlook regular training on the platform. This can lead to underutilization and missed opportunities.

Engaging with the platform fully can be challenging. Users may resist changes or find it complex at first. Regular updates and feedback sessions can help. In doing so, teams can maximize the benefits of the Hydropower Maintenance Platform. It transforms maintenance tasks, ensuring better energy production and reliability.

A hydropower maintenance platform is essential for ensuring the longevity of hydroelectric plants. Understanding the basics involves knowing its components and functions. These platforms often consist of software for data collection, analysis tools, and communication systems. They can help track equipment health and performance in real time. This immediate feedback signals impending issues, allowing for timely repairs.

Effective usage means familiarizing oneself with the platform. Users must learn how to navigate its features. Regular training sessions can enhance user skills. Despite the user-friendliness, many may find the interface overwhelming. This is common and requires patience. Make sure to utilize support resources for troubleshooting.

Analyzing data can sometimes be tricky. Users must not overlook the importance of interpretation. Wrong interpretations can lead to misguided maintenance strategies. Regularly revisit your data and assumptions. This can spark new insights or raise questions. Continuous reflection on usage is vital for improvement.

| Maintenance Task | Frequency | Tools Required | Estimated Duration | Responsible Personnel |

|---|---|---|---|---|

| Turbine Inspection | Monthly | Inspection tools, lubricant | 2 hours | Mechanical Engineer |

| Generator Maintenance | Quarterly | Multimeter, hand tools | 3 hours | Electrical Technician |

| Oil Level Check | Weekly | Oil gauge | 30 minutes | Plant Operator |

| Control System Review | Biannual | Specialized software | 4 hours | Control Systems Engineer |

| Safety Training | Annual | Training materials | 1 day | All Staff |

When exploring the key features of effective hydropower maintenance platforms, user-friendliness stands out. An intuitive interface can drastically reduce training time for new users. Clear navigation is essential; it allows technicians to quickly access necessary tools. A dashboard displaying real-time data enhances decision-making. These aspects prevent errors and improve overall efficiency.

Another crucial element is comprehensive reporting capabilities. A maintenance platform should generate detailed reports on equipment conditions, failures, and maintenance activities. This data helps identify recurring issues. Analyzing trends can lead to better preventive maintenance strategies. Without thorough data tracking, important insights may be overlooked.

Integration with other systems can also enhance functionality, yet many platforms struggle in this area. Seamless connections with inventory management or energy management systems can streamline operations. Additionally, mobile accessibility offers technicians the flexibility to manage tasks on-site. An effective platform should adapt to the field’s evolving needs while addressing potential gaps and challenges.

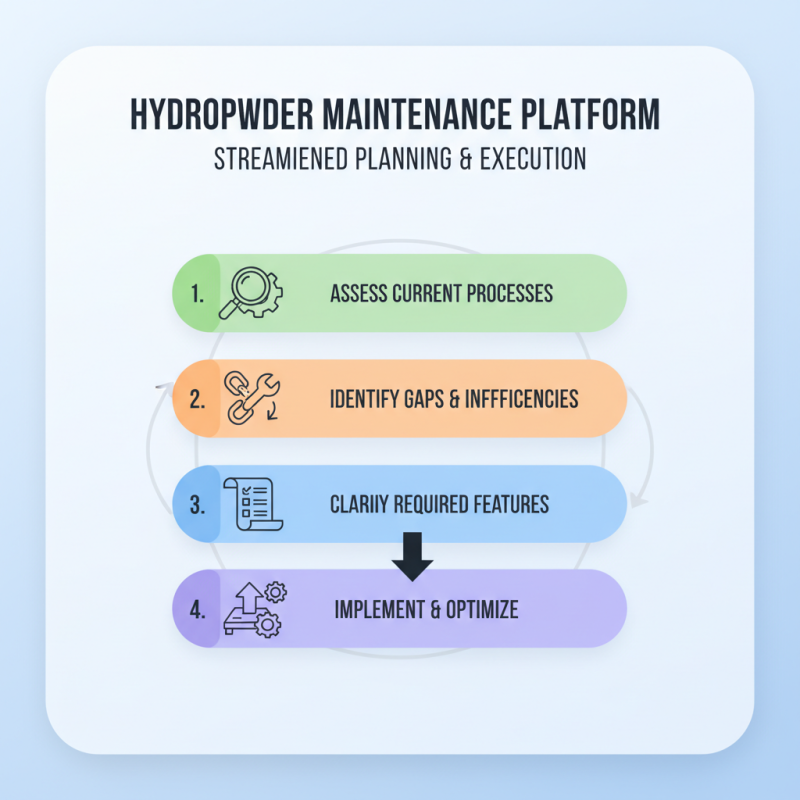

Implementing a hydropower maintenance platform requires careful planning and execution. Start by assessing your current maintenance processes. Identify gaps and inefficiencies. This initial assessment helps clarify what features you need from a platform.

Next, involve your team in the selection journey. Gather feedback from maintenance staff and engineers. Their insights can illuminate practical challenges. Ensure the software is user-friendly. It should be easy for everyone to navigate. A steep learning curve can cause frustration and slow down implementation.

Tips: Conduct regular training sessions. This keeps everyone updated on new features. Encourage team members to share experiences. Celebrate small wins as the platform becomes integrated into daily operations.

Consider data management as well. A hydropower maintenance platform should offer effective tracking of maintenance tasks. This lets you analyze performance over time. The data can reveal recurring issues or highlight areas needing improvement. However, collecting too much data can be overwhelming. Focus on key metrics that truly impact performance. This balance ensures you do not drown in unnecessary information.

In hydropower operations, effectively utilizing a maintenance platform can significantly improve efficiency. Begin by setting clear goals for your maintenance activities. Identify key performance indicators that align with your operational objectives. Regularly update these metrics to reflect changing conditions in your equipment and environment.

Training personnel is essential. Ensure that all team members understand how to use the platform. Hold training sessions to cover features, troubleshooting, and reporting. This may seem time-consuming but can prevent costly errors. Feedback from staff can reveal gaps in knowledge, prompting further training opportunities.

Documentation is critical. Record all maintenance activities meticulously within the platform. This creates a historical record for future reference. Analyze this data periodically. It can uncover patterns in equipment failures. Reflecting on these insights can lead to better decision-making and adjustments in maintenance strategies. Embrace the imperfections in your processes. Learning from them is key to continuous improvement in hydropower operations.

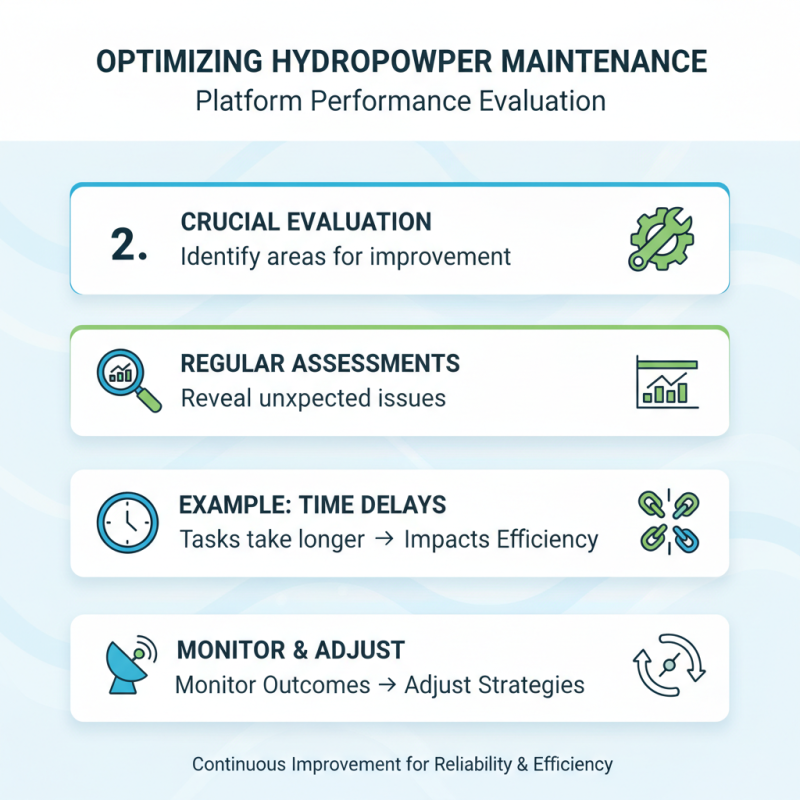

Evaluating the performance of a hydropower maintenance platform is crucial. It helps identify areas for improvement. Regular assessments can reveal unexpected issues. For example, maintenance tasks may take longer than anticipated. This delay can impact overall efficiency. Monitoring the outcomes allows teams to adjust their strategies accordingly.

Collecting data on maintenance activities is vital. Analyze completion rates, downtime, and costs. These metrics guide decision-making. If certain procedures consistently fail, revisiting them is essential. Consider employee feedback as a vital source of insight. They interact with the platform daily and can provide valuable input.

Creating a culture of reflection is necessary. Encourage teams to discuss what works and what doesn’t. Document lessons learned after each maintenance cycle. This documentation can highlight trends over time. Improvement is an ongoing process. Embrace the imperfections as learning opportunities. This mindset fosters a proactive approach to maintenance performance.