Leave Your Message

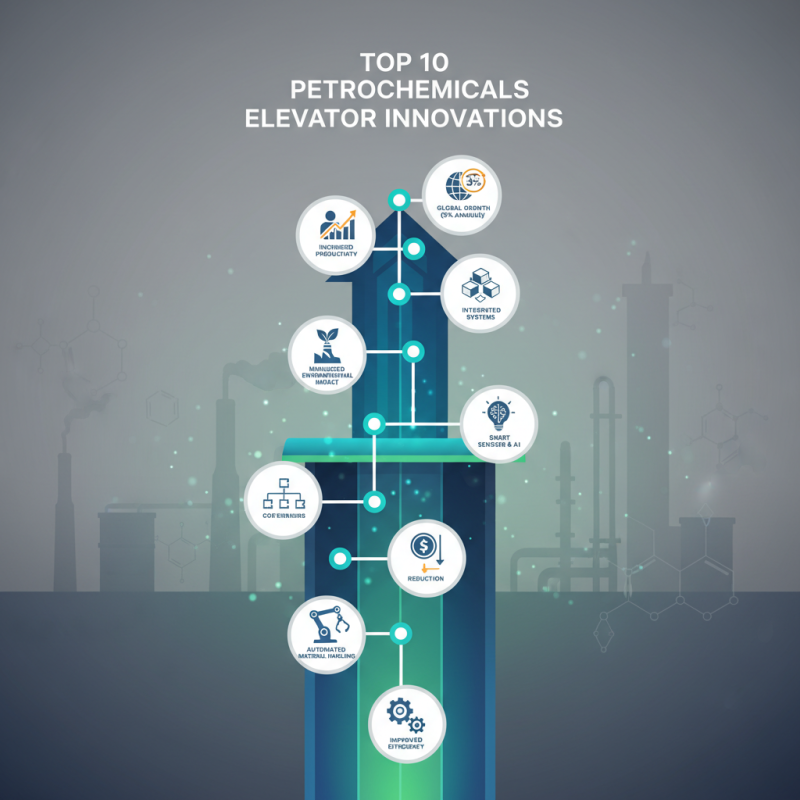

The petrochemical industry is undergoing a remarkable transformation. Petrochemicals Elevator innovations are at the forefront of this change. These advancements improve efficiency and productivity across the sector, addressing critical challenges.

Recent reports indicate that global petrochemical production is set to grow by 3% annually. However, companies face pressure to reduce costs and minimize environmental impacts. The emergence of new petrochemicals elevators is crucial in meeting these demands. They enhance material handling and streamline processes significantly.

Interestingly, while innovation drives progress, not all implementations succeed. Companies often overlook training and integration. Relying solely on technology fails to address human factors. As more firms adopt these innovations, the sector must continuously reflect on effective strategies for sustainable growth. Balancing technology with workforce development is essential for success in this dynamic industry.

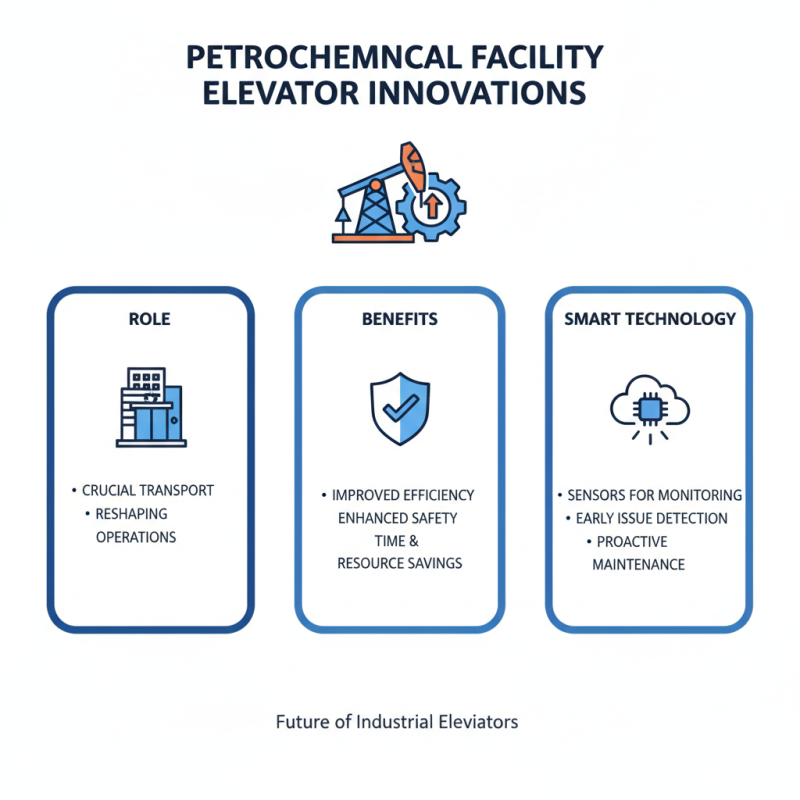

In petrochemical facilities, elevators play a crucial role. Their innovations are reshaping operations. These upgrades improve efficiency and safety. Smart technology is becoming common. Elevators are now equipped with sensors. These sensors monitor performance and detect issues early. This proactive maintenance saves time and resources.

Another key improvement is the use of advanced materials. Lightweight yet durable components enhance reliability. Elevators can now handle heavier loads. They operate faster, reducing wait times. Some facilities experiment with energy-efficient systems. These systems harness regenerative capabilities, cutting energy costs.

However, not all changes are perfect. Integrating new technologies can be challenging. Workers need training to adapt. Moreover, some older models may struggle with these upgrades. Continuous evaluation of these innovations is critical. The goal is to ensure they effectively support the industry's evolving needs.

The integration of IoT technology is reshaping the petrochemical elevator landscape. By incorporating smart sensors, elevators can now monitor their own performance in real-time. This leads to a reduction in downtime and a more efficient workflow. Data is collected continuously to identify potential issues. However, the challenge lies in ensuring that this data is accurately analyzed.

IoT applications enable predictive maintenance for elevators, preventing sudden breakdowns. Elevators use algorithms to gauge wear and make adjustments accordingly. Operators can track performance metrics remotely. Yet, relying heavily on technology can lead to oversights. If data interpretation fails, the entire system could falter. Failures in communication or cyber threats are concerns that need addressing.

Moreover, energy efficiency improves through IoT connectivity. Elevators optimize their routes based on traffic patterns. This not only saves time but also reduces energy consumption. Nevertheless, integration doesn’t come without risks. There is a learning curve for staff. Workers must adapt to new systems while managing existing operations. Balancing these elements is crucial for long-term success.

| Innovation | Description | Impact on Efficiency | IoT Integration | Expected Outcome |

|---|---|---|---|---|

| Smart Elevators | Utilize AI for optimal routing and scheduling. | 30% faster load times. | Real-time data on usage patterns. | Increased operational efficiency. |

| Predictive Maintenance | IoT sensors predict when maintenance is needed. | Reduces downtime by 25%. | Continuous monitoring of elevator systems. | Enhanced reliability. |

| Energy-Efficient Drives | Use next-gen electric drives that consume less power. | Up to 40% energy savings. | Data analysis for optimizing energy usage. | Lower operational costs. |

| Remote Monitoring | Allows monitoring of elevators from a central location. | Immediate response to issues. | Centralized data collection for analytics. | Increased safety and performance. |

| Advanced Safety Features | Implementing smart safety protocols and automatic shutdowns. | Reduced accidents by 50%. | IoT-driven safety alerts and notifications. | Improved workplace safety. |

| User-Friendly Interfaces | Touchless controls and intuitive navigation screens. | Faster boarding experience. | Data on user preferences collected. | Enhanced user satisfaction. |

| Mobile Integration | Users can call elevators using mobile apps. | Speeds up elevator access by 20%. | Real-time elevator status on smartphones. | Convenience and efficiency. |

| Data Analytics | Utilizes big data to improve elevator logistics. | Improves wait times by analyzing traffic patterns. | Advanced algorithms for peak time management. | Optimized scheduling. |

| Blockchain for Security | Enhances security through blockchain technology. | Increased data protection integrity. | Secure data transactions across devices. | Greater trust and transparency. |

| Robotic Assistance | Robots assist in elevator maintenance tasks. | Cuts maintenance labor costs by 15%. | Robots collect and analyze data on performance. | More efficient maintenance activities. |

The petrochemical industry is rapidly evolving, especially in elevator operations and maintenance. Automation plays a key role in this transformation. According to recent industry reports, automated systems can reduce downtime by up to 30%. This is critical for facilities that rely heavily on operational efficiency.

Integrating smart sensors is a growing trend. These sensors monitor the elevator's performance and predict maintenance needs. Data shows that predictive maintenance can save companies up to 25% on maintenance costs. Utilizing real-time data helps optimize operations and enhances safety protocols. However, some companies still hesitate to fully embrace these advancements. Resistance to change can hinder progress.

In recent years, safety enhancements in petrochemical elevators have gained significant attention. Various statistical analyses show alarming trends in elevator accidents. These incidents often lead to severe injuries and costly damages. An examination of data reveals that improper maintenance is a common problem. Frequent assessments enhance safety, but neglect is still widespread.

Innovations in technology aim to address these issues. Smart sensors and automatic shut-off systems are emerging trends. They monitor conditions in real-time and send alerts for potential hazards. However, the adoption rates are inconsistent across the industry. Many facilities still rely on outdated equipment, leaving potential risks unaddressed.

Training personnel on safety protocols is crucial. However, statistics indicate that many workers are not adequately trained. This gap creates vulnerabilities in an industry that demands precision. Visual reminders and regular drills could improve awareness. Despite advancements, there's a persistent need for reflection on safety practices and their implementation.

Elevators play a crucial role in modern infrastructure. As the industry evolves, sustainability becomes essential. Recent studies show that more than 30% of energy consumed in buildings comes from elevator systems. This fact pushes engineers to seek eco-friendly enhancements.

One promising area is regenerative drives. They capture energy during descent, converting it back into usable power. This innovation can reduce energy consumption by up to 50%. However, older elevator systems often lack this capability, and retrofitting them can be a complex process. The challenge lies in integrating new technologies without significant disruption.

Another emerging trend is the use of sustainable materials. High-quality, recycled steel and certified wood components can lower the environmental impact. Yet, not all manufacturers prioritize these materials. Some continue using traditional resources, reflecting a gap in industry practices. This inconsistency invites reflection on collective accountability for eco-improvements. Sustainable innovation requires a shared commitment, but the progress remains uneven within the sector.