Leave Your Message

The year 2026 brings exciting advancements in the petrochemical industry. Innovations in Petrochemical Facilities Lift technology are leading the way. These enhancements aim to improve efficiency and safety in operations.

Modern lift systems are becoming more sophisticated. They enhance the transportation of heavy materials within facilities. These systems operate with greater precision and control. However, challenges still exist. Many facilities face delays in implementing new technologies.

As companies seek to upgrade their equipment, budget constraints can hinder progress. Some organizations struggle to balance safety and productivity. Overall, the evolution of Petrochemical Facilities Lift systems highlights a need for continuous improvement. Embracing change is essential, but it requires thoughtful planning and collaboration.

In 2026, petrochemical facilities are expected to embrace cutting-edge lift technology innovations. These advancements focus on enhancing safety and efficiency. A report from the Global Petrochemical Association states that over 70% of facilities are prioritizing automated lift systems. Automation reduces human error while increasing productivity.

One key innovation is the implementation of smart sensors. These sensors monitor weight, speed, and environment in real-time. According to recent studies, such technology can improve response times by up to 40%. However, integration remains a challenge for many facilities. Traditional systems often resist modernization.

Another noteworthy trend involves the use of electric lift systems. These systems are not only more energy-efficient but also generate less noise. A 2025 industry analysis shows that electric lifts can decrease operational costs by up to 25%. Yet, they require significant upfront investment, which can deter adoption. Many organizations must reflect on their budget constraints and overall return on investment.

| Innovation Name | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Smart Lift Control Systems | Advanced monitoring and control systems that optimize lift performance. | Increased energy efficiency and reduced downtime. | 2026 |

| Automated Load Management | Systems that automatically adjust lift operations based on load conditions. | Enhanced safety and improved operational efficiency. | 2026 |

| Wireless Communication Technology | Integration of wireless technology for real-time data exchange and monitoring. | Improved decision-making capabilities and predictive maintenance. | 2026 |

| Augmented Reality Training Tools | Use of AR for training lift operators and maintenance personnel. | Faster training and improved operational safety. | 2026 |

| Enhanced Safety Features | Innovative safety mechanisms to prevent accidents and enhance worker safety. | Significant reduction in workplace injuries. | 2026 |

In 2026, petrochemical facilities are focusing on lift performance metrics for operational efficiency. Key metrics like energy consumption, downtime, and load capacity are critical. According to recent industry reports, energy costs can account for up to 30% of total operational expenses. Finding ways to reduce these costs through more efficient lifting mechanisms is essential.

Load capacity is another crucial factor. Many facilities aim for a 10% increase in their lifting capabilities this year. However, achieving this while maintaining safety standards proves challenging. Unplanned downtime due to lift malfunctions can result in significant financial losses. Reports indicate that a single hour of downtime can cost a facility up to $50,000.

Evaluating lift performance doesn't stop at metrics. It involves continuous improvement and innovative practices. Facilities are rethinking traditional lift maintenance schedules, introducing predictive maintenance instead. This approach can reduce unexpected failures. Yet, it's not without challenges. The need for skilled technicians to analyze data increases operational complexity. The road ahead may require more than just new technology; it demands a shift in workforce training and development.

Safety in the petrochemical industry is paramount. Lift systems play a critical role in ensuring this safety. Innovations in 2026 focus heavily on improving the reliability and efficiency of these systems. A recent industry report highlights that nearly 30% of accidents in petrochemical plants are linked to lift failures. This statistic underscores the need for enhanced safety protocols.

New technology now includes advanced sensors. These sensors can detect overload and prevent potential accidents. Incorporating machine learning can analyze historical data, predicting when maintenance is required. A study suggests that such predictive maintenance can reduce lift breakdowns by up to 50%. In addition, real-time monitoring systems can alert operators to unsafe conditions. This proactive approach is crucial in preventing incidents.

Despite these advancements, challenges remain. Many facilities still rely on outdated equipment. Implementing new technologies can be costly and complex. Additionally, training employees on these modern systems is essential yet often overlooked. There is always a risk of human error. Therefore, continuous training programs must be prioritized to maintain safety. The goal is not just compliance but the creation of a culture of safety.

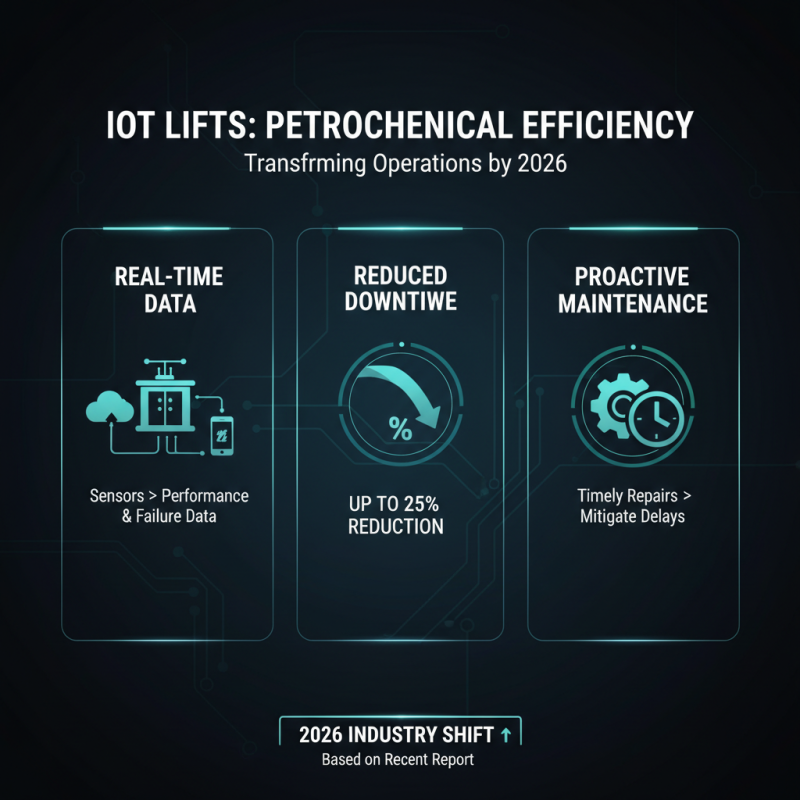

The integration of IoT into lift systems is transforming operational efficiency in petrochemical facilities. In 2026, this technology is expected to change the industry landscape significantly. A recent report highlights that IoT-connected lifts can reduce downtime by up to 25%. Sensors integrated into lifts provide real-time data on performance and potential failures. This proactive approach leads to timely maintenance and mitigates costly operational delays.

For instance, predictive analytics can identify irregular patterns in lift operations. This can help managers intervene before a breakdown occurs, saving time and money. Utilizing IoT platforms allows for centralized monitoring, making it easier to manage multiple facilities. However, challenges remain. Data security is a major concern, as more connectivity means increased risk of cyber threats. Facilities must address these vulnerabilities to maximize benefits.

Tips: Regularly update security protocols to protect IoT systems. Engage staff with training on data protection. Consider investing in robust cybersecurity measures to safeguard essential operational data. Balancing innovation and security is key to enhancing lift operations in the petrochemical sector. Ignoring these aspects can lead to significant setbacks.

In 2026, lift innovations in petrochemical facilities focus on sustainability. The shift toward greener technologies is evident. New lift systems are designed with eco-friendly materials. These innovations aim to reduce energy consumption. Energy-efficient lifts can significantly lower operational costs. The materials used must be recyclable or biodegradable.

Moreover, smart technology integration is crucial. Automated systems enhance efficiency and minimize human error. Data analytics play a role in predicting maintenance needs. This proactive approach reduces downtime. However, managing these advanced technologies can be challenging. Staff training is essential to ensure proper usage.

Tips: Always evaluate the environmental impact of new lifts. Consider the full lifecycle of materials. Regular training sessions can improve operational safety. Engage employees in sustainability practices to foster a culture of responsibility. These steps are vital for future-proofing operations.