Leave Your Message

In the dynamic world of oil refineries, efficiency is paramount. Experts like Dr. Jane Smith, a leading voice in oil refinery technologies, once stated, “Adopting innovative lift techniques is crucial for maximizing our operational capabilities.” Her insights highlight the significance of advanced Oil Refinery Lift methods.

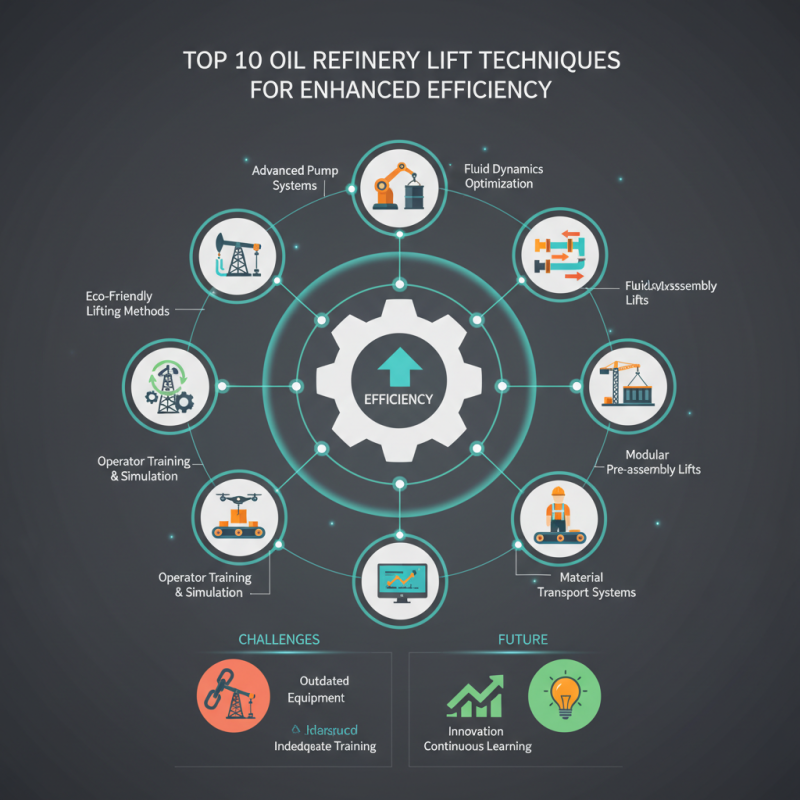

Implementing effective lift techniques can drastically improve workflow and reduce costs. For instance, utilizing advanced pump systems can enhance fluid movement. However, not all refineries are equipped to adopt these methods. Many face challenges with outdated equipment and inadequate training.

Reflecting on the current practices in the industry reveals areas for improvement. Some refineries still rely on traditional methods, which may hinder their efficiency. Investing in newer technologies and training is essential for staying competitive. As the sector evolves, companies must reassess their strategies. The future of Oil Refinery Lift lies in innovation and continuous learning.

Enhancing efficiency in oil refineries is critical. Employing effective lift techniques can maximize output and minimize costs. Among the popular methods, hydraulic lift systems stand out. They reduce the load on machinery and allow for better control of product flow.

Another technique involves the optimization of pump systems. Regular assessments can identify inefficiencies in pump performance. Consider adjusting pump speeds to match production demands. However, this requires careful monitoring. A small miscalculation can lead to unwanted delays.

Tips: Ensure routine maintenance on all lifting equipment. Small issues can escalate into costly downtime. Use data analytics to track performance trends. This allows for proactive adjustments, rather than reactive fixes. Remember, technology is only as good as its implementation. Each lift method needs to be tailored to specific refinery needs for maximum benefit.

Enhanced efficiency in oil refining is crucial for maximizing productivity and reducing costs. Efficient processes lead to higher output with less energy consumption. The refining process is intensive, and any improvements can yield significant benefits. For instance, optimizing the distillation column's performance can directly affect energy usage. Small adjustments can lead to large savings.

Moreover, environmental concerns are elevating the importance of efficiency. Lower emissions and reduced waste contribute to a cleaner operation. Implementing advanced technologies can facilitate compliance with regulations. However, adopting new methods involves challenges. Workers need proper training to adapt to updated systems, which can take time and resources.

In some cases, legacy systems may resist change. Modernizing these infrastructures requires careful planning. Investing in efficiency should balance immediate costs with long-term gains. Consequently, it is essential to measure and track progress continually. While striving for peak efficiency, facilities must remain flexible. Adaptability will play a vital role in overcoming unforeseen obstacles.

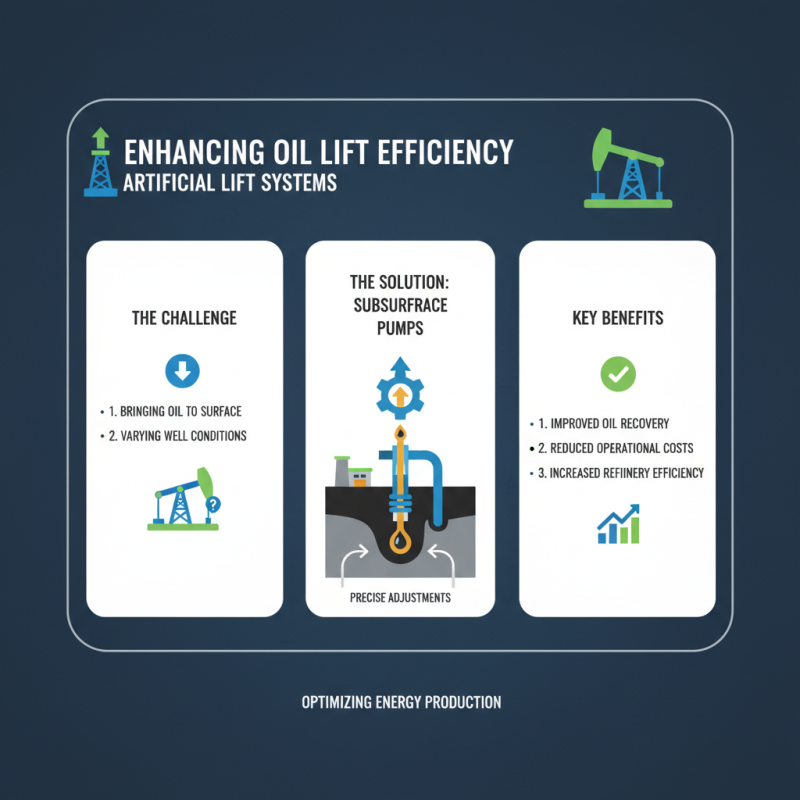

Enhancing oil lift operations is crucial for refinery efficiency. One of the prevalent techniques is using artificial lift systems. These systems employ subsurface pumps to bring oil to the surface more effectively. However, they often require precise adjustments to fit different well conditions. Improper calibration can lead to inefficiencies and increased operational costs.

Another technique is optimizing gas lift operations. This process injects gas into the well to reduce fluid density. It can significantly increase the ease of lifting oil. However, operators need to carefully monitor the gas injection rate. Too much gas can create foaming, which complicates extraction.

Lastly, leveraging digital technology plays a vital role. Implementing real-time monitoring can provide insights into well performance. Yet, reliance on technology can lead to overconfidence. Operators must balance data with their experience to avoid pitfalls. Every improvement technique requires constant evaluation and adjustment to maintain peak efficiency.

Innovative lifting techniques in oil refineries are crucial for enhancing operational efficiency. Recent reports indicate that lifting inefficiencies can lead to a 20% increase in operational costs. This highlights the need for refined methods that are both safe and effective in heavy lifting scenarios.

One promising technology is the use of automated lifting systems. These systems can improve precision and reduce human error. According to industry data, automation can lead to a 30% reduction in downtime during maintenance operations. However, there are challenges. The initial investment may be substantial, and operators require training to adapt to new systems.

Additionally, advancements in material science are shaping lifting tools. Lightweight, high-strength materials can reduce the load on lifting mechanisms. Studies reveal that using composite materials can enhance lifting capacities by up to 40%. Yet, concerns persist regarding long-term durability and maintenance. These factors warrant careful consideration by refinery management teams. Balancing innovation and practical implementation remains a critical endeavor in the industry.

| Lift Technique | Description | Efficiency Gain (%) | Implementation Cost ($) |

|---|---|---|---|

| Hydraulic Lifting Systems | Utilizes hydraulic pressure for safe and efficient lifting of heavy equipment. | 25% increase in efficiency | 15,000 |

| Robotic Arms | Automates heavy lifting tasks, reducing labor costs and risk of injury. | 30% increase in efficiency | 50,000 |

| Cranes with Improved Load Capacity | Enhances lifting capability, allowing for larger loads. | 20% increase in efficiency | 75,000 |

| Smart Sensor Technology | Integrates IoT sensors to monitor load and optimize lifting operations. | 15% increase in efficiency | 10,000 |

| Modular Lifting Systems | Flexible systems that can be adjusted based on specific lifting needs. | 18% increase in efficiency | 30,000 |

| Advanced Safety Protocols | Enhances worker safety while optimizing lifting processes. | 10% increase in efficiency | 5,000 |

| Pneumatic Hoisting Solutions | Leverages air pressure for lifting, suitable for specific refinery tasks. | 22% increase in efficiency | 20,000 |

| Electronic Load Monitoring | Tracks weight in real-time to prevent overloading and improve safety. | 12% increase in efficiency | 8,000 |

| Training and Skill Development | Investing in personnel skills leads to improved operational efficiency. | 15% increase in efficiency | 3,000 |

| Wireless Remote Controls | Allows operators to control lifting equipment from a safe distance. | 14% increase in efficiency | 12,000 |

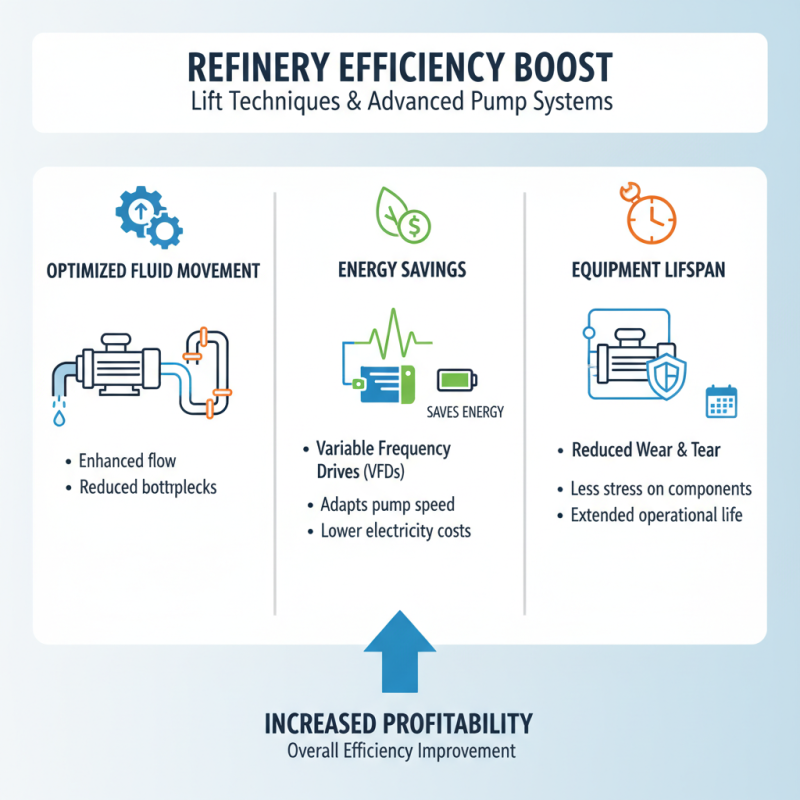

Implementing lift techniques in refineries can significantly boost efficiency. One common approach is utilizing advanced pump systems. These systems improve fluid movement and reduce energy consumption. For example, using variable frequency drives can optimize pump speeds based on demand. This adaptation not only saves energy but also extends equipment lifespan.

Another critical factor is staff training. Operators should understand the intricacies of new lift technologies. Workshops and hands-on sessions can be effective. However, there is often a gap in knowledge retention among staff. Regular refresher courses can address this issue. It’s important to create a culture of continuous learning. The more informed the team, the better the operations.

Monitoring and data analysis are also essential. Refineries need a system to track performance metrics. It helps identify areas for improvement. However, many facilities struggle with data overload. Filtering out irrelevant information can be daunting. Focusing on key performance indicators is vital. Ensuring that the data is actionable is a challenge that should not be overlooked.