Leave Your Message

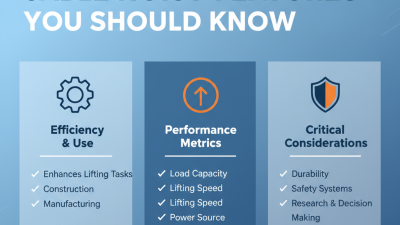

In the fast-evolving realm of industrial equipment, the demand for efficient operations is crucial. The Electric Hoist Remote plays a pivotal role in enhancing efficiency. According to a report by Market Research Future, the electric hoist market is projected to grow at a CAGR of 5% from 2021 to 2026. This growth underscores the significance of remote control technology in improving lifting operations.

The incorporation of Electric Hoist Remotes allows operators to manage loads from a safe distance. This feature is vital in minimizing workplace accidents. Data from the Occupational Safety and Health Administration shows that improper lifting causes numerous injuries annually. Consequently, implementing advanced remotes can mitigate these issues. Many users, however, still grapple with choosing the right remote models.

Not all Electric Hoist Remote options are equal, and this lack of standardization can lead to inefficiencies. Some remotes may not meet specific industry needs or compatibility requirements. This inconsistency emphasizes the need for thorough research and informed decisions when selecting the appropriate remotes. Proper attention to these details can significantly enhance operational performance and safety.

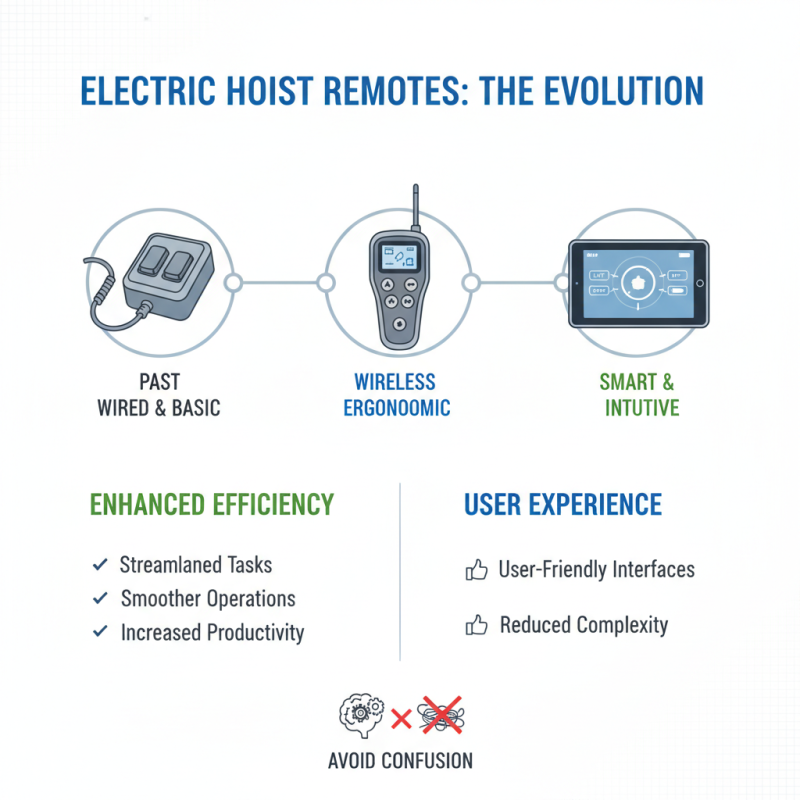

Electric hoist remotes have evolved significantly. Modern technology offers a variety of options that enhance efficiency and user experience. These remotes can streamline lifting tasks, making operations smoother. Many designs focus on user-friendly interfaces, but some still have complexity that can confuse operators.

Wireless remotes are a popular choice. They reduce tethering issues, promoting flexibility. However, battery life can be a concern. It's essential to monitor power levels to prevent unexpected downtime. Additionally, some units feature safety lock mechanisms, but not all offer this function.

Touchscreen interfaces are gaining traction. They can present information clearly and allow for customization. Yet, these screens might not be ideal for harsh environments. Many operators find traditional buttons easier to manage, especially in demanding situations. Constant feedback from users is vital to improve these technologies.

When choosing the right electric hoist remote, several key features must be considered. The control range is vital. Ensure the remote can operate from a safe distance. This distance should be adequate for effective monitoring during lifting operations. Look for models that boast reliable signal transmission to avoid interruptions.

Another important feature is ergonomics. A comfortable grip minimizes strain during prolonged use. Lightweight materials contribute to ease of operation. Tactile buttons enhance usability, especially in challenging conditions. Consider whether the remote is waterproof or resistant to dust. This can significantly improve durability.

Tips: Regular maintenance of the remote is crucial. Always check batteries and connections. A backup remote may save time in emergencies. Test the range periodically to ensure safety. Finding a remote that suits your specific needs can improve overall efficiency. The right features lead to smoother and safer operations.

This chart illustrates the comparison of key features in the top 10 electric hoist remote options, focusing on factors such as range, battery life, ease of use, weight capacity, and durability.

When choosing between wireless and wired electric hoist remotes, both options have distinct advantages. Wireless remotes offer flexibility and mobility. Operators can move freely without being tethered. This is particularly useful in large areas where a direct line of sight may not always be possible. However, battery life can be a concern. If batteries run low, operators might find themselves without control at critical moments.

Wired remotes, on the other hand, provide a reliable connection. They do not rely on batteries or wireless signals. This can be important in environments where interference might occur, such as in industrial settings with heavy machinery. Yet, the restriction of cables can limit movement. Operators must remain close to the hoist, which can reduce overall efficiency in some tasks.

Both types have unique drawbacks. Wireless systems can face interference, while wired systems may lead to tangles or damages. Understanding the specific needs of the job is essential. The decision should reflect the work environment and the level of mobility required. Balancing efficiency with reliability is key to selecting the best remote for any electric hoist.

The landscape of electric hoist remote control technology is rapidly evolving. Recent industry reports highlight a shift towards more intuitive user interfaces and enhanced safety features. According to a 2023 market research study, over 70% of consumers prefer remotes with ergonomic designs. This demand drives innovation in remote control technology.

Tip: Look for remotes that offer customizable buttons. This feature can streamline your operations significantly.

Additionally, advancements in wireless technology are shaping industry standards. Systems now integrate seamlessly with mobile devices, allowing for real-time monitoring. A survey indicated that users find remote controls with digital displays easier to manage. Yet, there are concerns about reliability. Not all remotes maintain consistent connectivity, causing potential operational delays.

Tip: Regularly test your remote systems to minimize downtime.

As user expectations rise, manufacturers are under pressure to deliver reliable, efficient products. The competition is fierce, pushing companies to innovate. Industries must stay vigilant to adapt to these trends. After all, navigating this evolving market requires companies to rethink their remote control strategies.

| Model | Weight Capacity (lbs) | Control Range (ft) | Battery Life (hours) | Price Range (USD) |

|---|---|---|---|---|

| Model A | 2000 | 100 | 8 | 150-200 |

| Model B | 3000 | 120 | 10 | 200-250 |

| Model C | 4000 | 150 | 12 | 300-350 |

| Model D | 2500 | 80 | 9 | 175-225 |

| Model E | 3500 | 140 | 11 | 250-300 |

| Model F | 1500 | 60 | 7 | 100-150 |

| Model G | 3000 | 130 | 10 | 225-275 |

| Model H | 4000 | 160 | 12 | 320-370 |

| Model I | 2500 | 90 | 8 | 180-230 |

| Model J | 3000 | 110 | 10 | 210-260 |

When evaluating electric hoist remotes, performance metrics play a pivotal role. Effectiveness is often measured by user satisfaction and ease of control. According to a recent industry report, remotes with an ergonomic design can enhance user comfort by 30%. Safety is equally vital. The best remotes boast safety ratings above 95%, reducing accident risks significantly. Features like emergency stop buttons and overload indicators improve operator confidence.

**Tip:** Choose remotes that allow programmable features. This offers flexibility for various lifting tasks. Many users have found that custom settings can streamline operations, boosting overall efficiency.

Additionally, consider range and signal reliability. High-frequency remotes operate effectively up to 300 feet. Yet, some users report interference issues in crowded environments. Testing remotes in real conditions might uncover some shortcomings. Modern remotes also focus on data feedback, allowing operators to monitor loads in real-time.

**Tip:** Regularly inspect battery life and signal strength. This proactive approach can prevent unexpected failures. Remember, not all remotes provide reliable alerts. Assessing these features can lead to more informed choices.