Leave Your Message

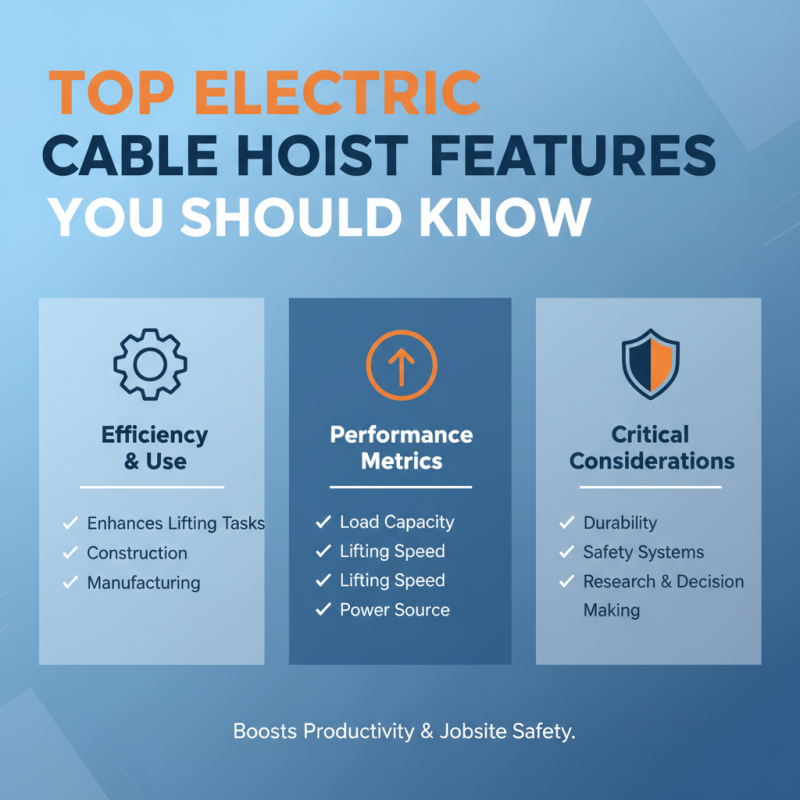

When considering the essential features of an Electric Cable Hoist, it’s vital to assess their practical benefits. These devices enhance efficiency in various lifting tasks. They are widely used in construction and manufacturing industries.

Key elements include their load capacity and lifting speed. Users must also evaluate the power source. Electric Cable Hoists can be more convenient than manual options. However, not all hoists are created equal. Features vary widely, and not knowing specifics can lead to poor decisions.

While the importance of durability cannot be overstated, some might overlook safety features. A hoist may be powerful yet lack adequate safety systems. Investing time in research can prevent costly mistakes. Knowing what to look for is crucial for any potential buyer. The right Electric Cable Hoist can make a significant difference in productivity and safety on the job.

When selecting an electric cable hoist, key specifications play a crucial role. One of the most important factors is the weight capacity. Many hoists list different ratings. Knowing the exact load you plan to lift is essential. If the hoist is under-rated, it can fail, leading to accidents. Consider your lifting height too. Some tasks require a longer lift. A hoist that doesn't meet these needs will not function effectively.

The speed of the hoist also matters. A faster hoist saves time, but control can be compromised. Understand your workflow requirements. Sometimes, a slower, more precise hoist is better than a speedy one. Look at the power source as well. Electric hoists can differ in voltage and type. Ensure that your site has the right electrical setup. Don't forget about safety features. Emergency stops and over-load protection are crucial for preventing damage and accidents, but some models may lack these.

Reflect on what features are absolutely necessary for your tasks. Choosing the right electric cable hoist requires careful consideration of these specifications.

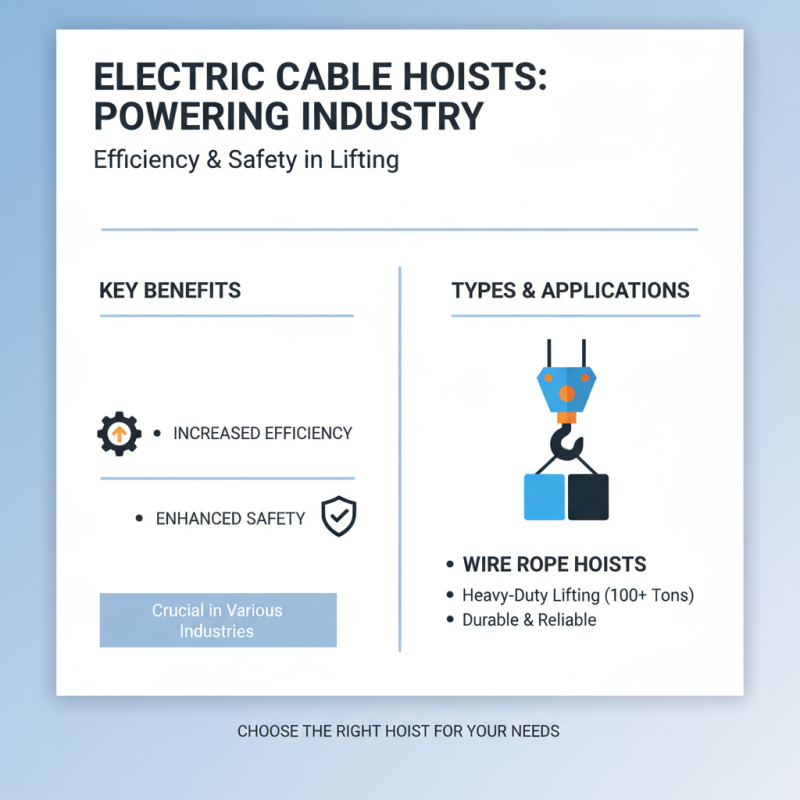

Electric cable hoists are crucial in various industries. They increase efficiency and safety in lifting operations. The right hoist type depends on specific applications. For instance, wire rope hoists are ideal for heavy-duty lifting, often reaching capacities over 100 tons. Their design ensures durability and reliability in harsh conditions.

Chain hoists, on the other hand, are versatile. They work well in confined spaces and can handle loads up to 10 tons. These hoists are common in construction and manufacturing settings. Their ease of use makes them a go-to option for many operators. However, lifting capacity and safety features should always be considered.

The global electric hoist market was valued at approximately $2 billion in 2022. It's projected to grow significantly. Factors like automation and safety regulations drive demand. Some users often overlook regular maintenance. This can impact performance and safety. Awareness of proper usage and limitations is vital. Training operators can help mitigate risks and improve efficiency.

When investing in an electric cable hoist, safety features are paramount. Look for overload protection. This feature automatically shuts off the hoist when it exceeds weight limits. It prevents accidents and equipment damage.

Emergency stop buttons are essential. They allow quick stoppage in case of an emergency. An easily accessible button can save lives. Ensure the button is visible and within reach.

Here’s a tip: always inspect the hoist before use. Check cables for fraying or damage. Regular maintenance reduces risks.

Another safety feature is limit switches. These prevent the hoist from moving too high or too low. They help control the movement of loads. Improper movements can lead to serious injuries.

Don’t forget about the hoist's design. Some have a stable base for better stability. Stability is crucial when handling heavy loads. A top-heavy hoist can tip over, causing accidents.

Keep safety in mind with all hoists. Remember, it's better to be safe than sorry. Investing time in understanding safety features pays off.

| Feature | Description | Importance |

|---|---|---|

| Load Capacity | The maximum weight the hoist can lift safely. | Critical for ensuring safe operation and preventing overloads. |

| Lift Speed | The speed at which the hoist can lift or lower the load. | Affects the efficiency of operations. |

| Safety Features | Includes emergency stop button, limit switches, and overload protection. | Ensures user safety and protection against mechanical failures. |

| Control System | Type of controls such as pendant, remote, or automatic. | Impacts ease of use and operator comfort. |

| Durability | Material quality and resistance to wear and environmental factors. | Essential for long-term operation and reliability. |

| Portability | Ease of transport and setup across different sites. | Important for jobs requiring mobility. |

When choosing an electric cable hoist, understanding load capacity is crucial. Load capacity determines how heavy an object the hoist can lift safely. It is often expressed in pounds or kilograms. If you miscalculate this number, you risk damaging your equipment or causing an accident. Many operators underestimate the load they need to lift. This mistake can lead to equipment failure and severe consequences.

Beyond the numbers, consider the real-world application. What's on the line? Improper load capacities can affect your workflow. A hoist rated for 1,000 pounds might falter with a 1,200-pound load. Many operators rely on instinct instead of calculated measurements. This reliance can lead to dangerous situations. Regular training and assessments of load capacities are essential. They help avoid oversights and ensure smooth operations.

The maintenance of the hoist should also align with its load capacity. Regular checks for wear and tear can help manage the risk of lifting heavy objects. A neglected cable might snap unexpectedly. Operators should regularly inspect cables, hooks, and motors. This attention to detail maintains the hoist's reliability. Performance is not solely about lifting power but also about consistent, safe operation.

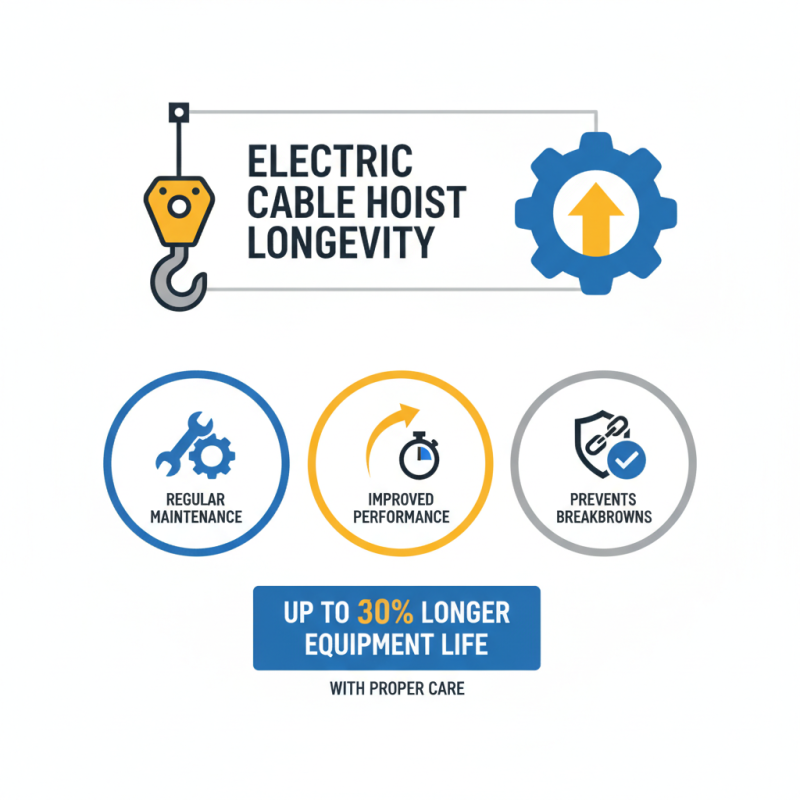

Maintaining the longevity of electric cable hoists is crucial for operational efficiency. Regular maintenance can improve performance and prevent costly breakdowns. According to industry reports, proper maintenance can increase equipment life by up to 30%. This statistic highlights the importance of care in extending the useful life of hoists.

**Tips:** Regularly inspect the cables for wear and tear. Look for frays or kinks. Replace any damaged cables immediately to avoid accidents. Moreover, ensure that the hoist is properly lubricated. This simple step can reduce friction and prolong moving parts' life.

Keep a maintenance log. Documenting repairs and inspections helps track performance trends. Certain signs, like unusual noises or decreased lifting capacity, require immediate attention. Reflect on these signals; they often indicate underlying issues needing resolution. Without a proactive approach, performance reliability may decline significantly, leading to unplanned downtime and increased operational costs.