Leave Your Message

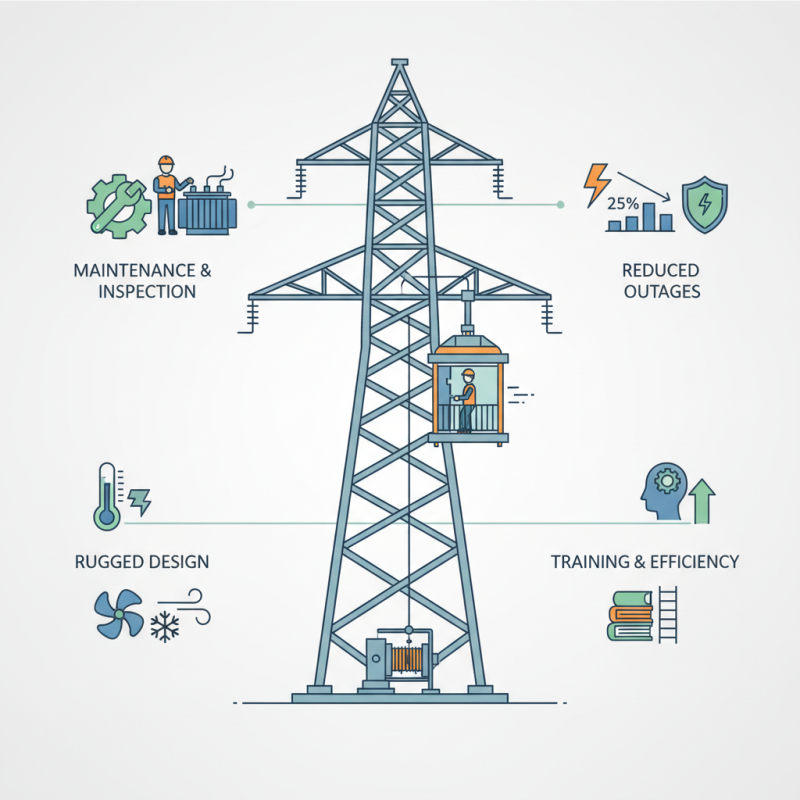

The Power Grid Tower Elevator plays a crucial role in modern energy distribution. These elevators facilitate maintenance and inspection tasks on power grid towers, ensuring safety and efficiency. According to a report by the International Energy Agency, about 25% of power outages stem from equipment failure. Regular maintenance can significantly reduce these incidents.

The design of the Power Grid Tower Elevator is tailored for rugged environments. It is engineered to withstand high winds and extreme temperatures. Safety features include emergency descent systems and anti-slip surfaces, as maintenance workers often face hazardous conditions. Despite these advancements, challenges remain. Operators sometimes encounter mechanical failures, which can lead to delays.

Efficient inspection processes can improve overall grid performance. Still, training for technicians is necessary. Industry standards recommend regular training on the latest equipment and safety procedures. Ultimately, enhancing the Power Grid Tower Elevator’s functionality is essential for a reliable energy infrastructure. Addressing these challenges is vital for future developments.

Power grid tower elevators are essential tools in electricity distribution. They provide a safe and efficient way to access power lines for maintenance and repair. The design of these elevators allows workers to reach significant heights without the risk associated with ladders. These elevators are often attached to towers, enabling quick movement.

The primary purpose is to enhance safety and productivity. Workers can operate from an elevated platform while handling tools. This method minimizes accidents. However, the design and functionality can have drawbacks. For instance, the tower’s structure may limit space. Maintenance of the elevator itself can become a challenge. Regular checks are necessary to ensure reliability, which can often be overlooked.

Furthermore, not all power grid tower elevators are identical. Some may lack advanced features. This variation can lead to inefficiencies in specific conditions. Thus, workers must fully understand their equipment. Familiarity can significantly reduce risks involved. Investing time in training is crucial for best practices. Ultimately, the balance between technology and human skill is essential for optimal performance.

Power grid tower elevators are specialized devices designed to assist workers in maintaining and repairing overhead power lines. These elevators are vital for ensuring safety and efficiency while operating at great heights. They help reduce the physical strain on workers and facilitate quick access to high structures.

The components of a power grid tower elevator include a platform, which provides a stable area for workers. This platform often has safety rails to prevent falls. There are also hoisting systems that utilize electric or hydraulic methods to lift and lower the platform. These systems must be reliable, as they play a crucial role in worker safety. Control mechanisms allow operators to manage the elevator's movements precisely, ensuring that they can respond to changing conditions effectively.

Additionally, these elevators are equipped with safety devices, like emergency brakes, to prevent free fall. Regular inspections of all components are essential. Sometimes, components wear out faster than expected, causing potential safety risks. Addressing these concerns promptly is vital but often overlooked in practice. Thoughtful operation of the system can make a significant difference in performance and safety for all involved.

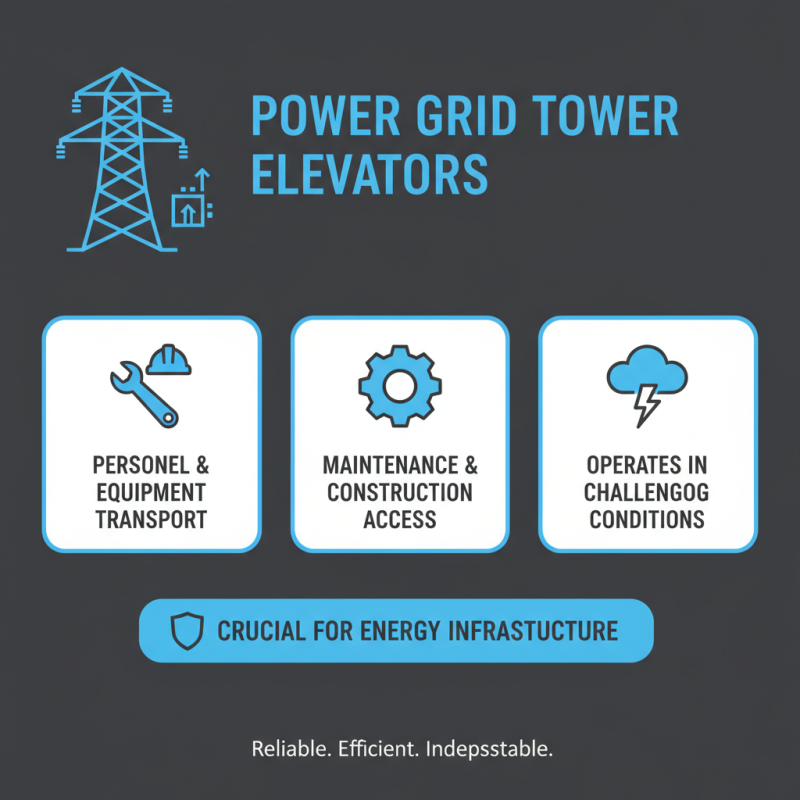

Power grid tower elevators serve a crucial role in maintaining energy infrastructure. These elevators are designed to transport personnel and equipment to significant heights on power grid towers. Their ability to operate in challenging conditions makes them indispensable for utility companies.

The mechanism of operation focuses on precision and safety. Typically, these elevators use a cable system with pulleys. The cables connect to a counterweight, which balances the load. This setup ensures smooth vertical travel. Safety features include emergency brakes and an automatic shutoff. They are designed to prevent accidents, given the heights involved.

Maintaining these elevators is essential. Regular inspections catch wear and tear. However, some systems may still face unexpected malfunctions. Training for operators is not always comprehensive. Mistakes can occur, leading to dangerous situations. Operators must stay alert and prepared for challenges they might encounter in the field.

Power grid tower elevators are essential for maintaining and inspecting power lines. They help workers access hard-to-reach areas safely. Safety features are vital in this equipment. For instance, emergency brakes prevent falls. These brakes engage automatically if there’s a malfunction. Additionally, safety harnesses are required for every worker. Every person must be trained to use the elevator correctly.

Regular maintenance is crucial to ensure safety. Controllers and motors should be checked often. Any wear and tear must be addressed immediately. It’s essential to inspect cables for fraying or damage as well. Routine inspections help identify risks before they become severe problems. However, even with regular maintenance, issues can still arise. Workers need to be vigilant and report any irregularities. Planning for potential faults is an essential part of the job. Understanding that not everything may go as planned is important.

| Feature | Description |

|---|---|

| Purpose | Transport maintenance crews and equipment to power grid towers safely |

| Construction Material | Usually made of steel to withstand harsh environmental conditions |

| Height Capacity | Can range from 30 to 100 feet depending on the tower |

| Operating Mechanism | Utilizes a winch and pulley system for vertical movement |

| Safety Features | Includes emergency stop, backup power systems, and safety harnesses |

| Maintenance Practices | Regular inspections, lubrication of moving parts, and replacement of worn components |

| Weight Capacity | Typically supports up to 1,000 pounds for safe operation |

| Training Requirements | Operators must complete safety training and certification |

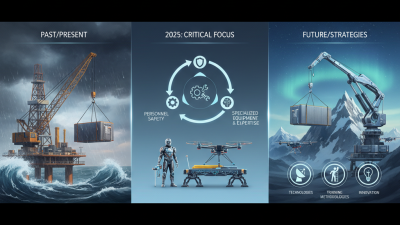

Power grid tower elevators play a crucial role in modern electricity management. These devices provide safe, efficient access to high transmission lines. Workers can quickly reach necessary heights without cumbersome climbing gear. As a result, routine maintenance and inspection become more manageable. This means fewer delays in service and improved grid reliability.

The applications of power grid tower elevators extend beyond simple maintenance. They facilitate quicker repairs during outages. A swift response can significantly reduce downtime. Additionally, these elevators enhance safety for the workers involved. Climbing tall towers without adequate support poses risks. However, with a reliable elevator, the chances of accidents decrease.

Despite their benefits, there are challenges to consider. The installation and maintenance of these elevators can be costly. Some regions may face delays in implementation due to budget constraints. Moreover, training for operators is essential to avoid mishaps. Ensuring that the workforce is educated on the technology is vital. Balancing cost and safety is an ongoing conversation in energy management.