Leave Your Message

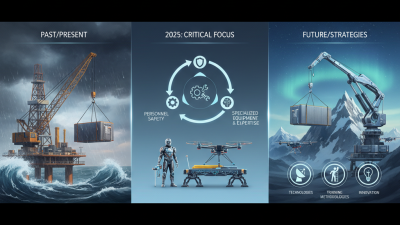

In the rapidly evolving petrochemical industry, the concept of a "Petrochemicals Elevator" has gained significant attention. This term refers to advanced systems designed to enhance the efficiency of petrochemical production and distribution. According to a recent market analysis by Global Industry Analysts, the global petrochemicals market is projected to surpass $1 trillion by 2026, highlighting the importance of innovative technologies like the Petrochemicals Elevator.

Experts emphasize the critical nature of these systems. Dr. John Smith, a leading figure in petrochemical technology, mentioned, "The Petrochemicals Elevator is essential for optimizing processes and reducing waste." These elevators not only streamline operations but also contribute to sustainability goals. Yet, the implementation of such technologies is not without challenges. Companies must navigate logistical complexities and integrate new systems while upholding safety standards.

Despite their promise, the effectiveness of Petrochemicals Elevators can vary significantly across different operations. Some companies struggle with adaptation, leading to underperformance. Continuous improvement and feedback are vital for making these systems truly beneficial. The journey of innovation in this field requires an unwavering commitment to refining processes and learning from both successes and setbacks.

The petrochemicals elevator is a crucial component in the chemical industry. It refers to specialized equipment designed to transport raw materials and finished products throughout production facilities. This elevating technology enhances operational efficiency, ensuring safety and speed during handling processes.

According to recent data, the global petrochemical market is projected to grow significantly, with an estimated value of $1.5 trillion by 2030. The need for effective logistics, such as petrochemicals elevators, becomes more pressing as production scales up. Many facilities still rely on outdated systems that may not handle increased volumes efficiently. Inadequate transport solutions could lead to bottlenecks and increased costs.

The role of a petrochemicals elevator extends beyond mere transportation. It ensures compliance with safety regulations while minimizing product contamination risks. Yet, some plants struggle to adopt best practices, resulting in inefficiencies. Investing in modern elevating systems is essential. However, a significant portion of facilities finds it challenging to justify such capital expenditures. Balancing costs with operational improvements remains a difficult task in a competitive landscape.

Petrochemicals elevators are vital in modern chemical production. They transport materials efficiently, enabling seamless integration in facilities. The key components of these systems ensure smooth operation and productivity.

One critical component is the conveying system. This includes various types of elevators like bucket elevators and screw conveyors. According to a recent industry report, approximately 33% of operational downtime is linked to inefficiencies in these systems. Thus, ensuring the right technology is crucial for minimizing delays.

Another important aspect is the control mechanisms used in these elevators. Automated controls help manage the flow of materials precisely. This reduces human error. Data suggests that improperly calibrated systems can lead to 15% losses in production capacity. Investing in reliable controls can significantly enhance overall efficiency.

Despite advancements, challenges remain. Many facilities struggle with maintenance and upgrades. Often, older systems do not meet current safety standards. Addressing these gaps is essential for future growth in the petrochemical sector.

Petrochemicals play a vital role in modern industry. They serve as the building blocks for countless products, including plastics, fertilizers, and pharmaceuticals. The petrochemical industry has grown significantly over the years. According to recent reports, the global petrochemicals market reached approximately $450 billion in 2022 and is projected to grow by 5% annually through 2030.

Elevators in petrochemical plants are crucial. They transport raw materials and finished products efficiently. This equipment ensures that the processes run smoothly and safely. Elevators reduce the manual handling of materials, which can prevent accidents. However, maintenance is often overlooked. Regular inspections are necessary to avoid costly downtimes.

Petrochemical elevators also contribute to sustainability efforts. By optimizing transport processes, they help in reducing energy consumption. A study indicated that efficient lifting systems can save up to 30% in energy costs. This efficiency can lead to lower carbon emissions. Yet, many facilities struggle with outdated systems. Updating technology is essential to keep up with industry standards.

| Function | Description | Applications | Benefits |

|---|---|---|---|

| Material Handling | Facilitates the movement of raw materials and finished products within petrochemical plants. | Transporting polymers, chemicals, and other bulk materials. | Increases efficiency and productivity in material processing. |

| Safety Enhancements | Reduces risks of spills and accidents during material transport. | Used in operations involving hazardous materials. | Improves workplace safety standards. |

| Energy Efficiency | Optimizes energy usage during the material handling processes. | In processing plants where energy consumption is critical. | Decreases operational costs and carbon footprint. |

| Integration with Automation | Can be incorporated into automated systems for enhanced control. | Used in robotic and automated material handling systems. | Increases operational efficiency and accuracy. |

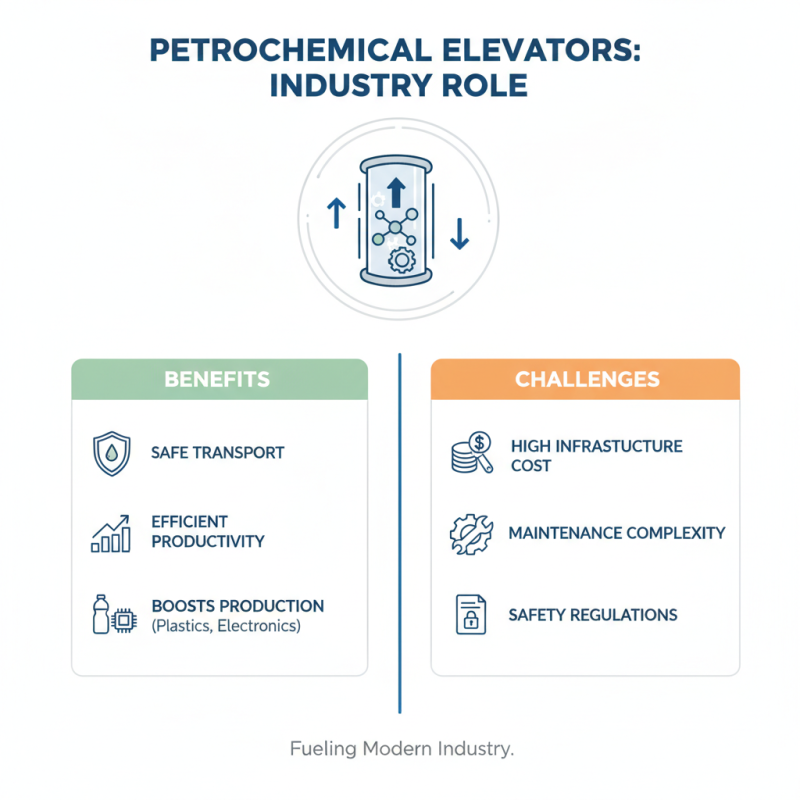

Petrochemical elevators have a unique role in industry. They transport petrochemical products safely and efficiently. This efficiency boosts production rates in various sectors, including plastics and electronics. However, there are benefits and challenges associated with their use.

One clear benefit is reduced environmental risk. These elevators minimize spills and leaks. By containing hazardous materials, they protect workers and the environment. Yet, the cost of implementing such systems can be high. Cutting-edge technology often demands substantial investment. Some companies may struggle with this upfront cost.

Tips: Regular maintenance is crucial for these elevators. A small issue can escalate into a significant problem. Additionally, staff training is essential. Employees need to understand safety protocols fully.

Another challenge arises from operational errors. Human mistakes can lead to serious accidents. Continuous training and adherence to safety standards are necessary. Keeping a checklist for operational procedures can help. These practices enhance overall safety and efficiency.

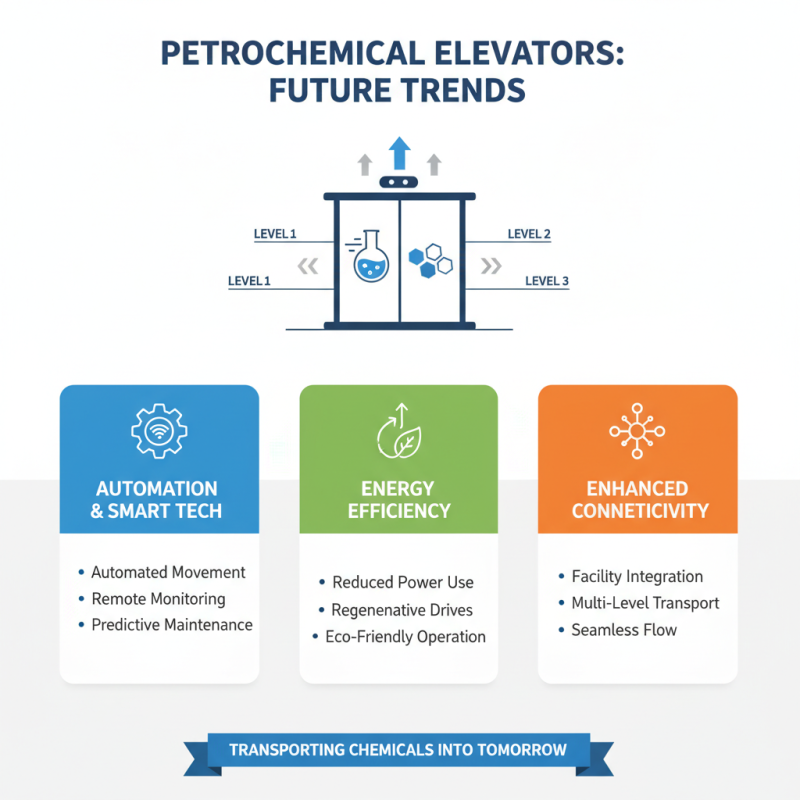

Petrochemical elevators are crucial in the transportation of chemical products. Future trends indicate a shift towards automation and smart technology. These elevators will connect different levels in facilities, moving fluids and solids more efficiently. Improvements in energy efficiency are also on the horizon.

Innovation in materials helps in preventing leaks and spills during transport. Smart sensors will monitor conditions in real-time. This will ensure safety and efficiency, reducing downtime. These advancements could significantly lower operational costs.

Tips for optimizing petrochemical elevator usage include regular maintenance checks. Inspect for wear and tear. Implementing preventive measures can save time and resources. Staff training on new technologies is crucial. Understanding innovations can improve safety. Adapting quickly to changes will strengthen industry performance.