Leave Your Message

Lng Tanks Hoist plays a crucial role in the transportation of liquefied natural gas. Understanding its workings can shed light on its importance. This hoisting system is designed to lift and move heavy LNG storage tanks safely.

These tanks are essential for storing gas in a liquid state. The design of the Lng Tanks Hoist ensures efficiency and safety during operation. However, the complexity of the mechanism can lead to operational challenges.

Users must be aware of potential issues, like equipment malfunctions. Regular maintenance is crucial to avoid accidents. As we explore the Lng Tanks Hoist, we'll look at its components and how they work together. This examination reveals both the strengths and weaknesses of this vital system.

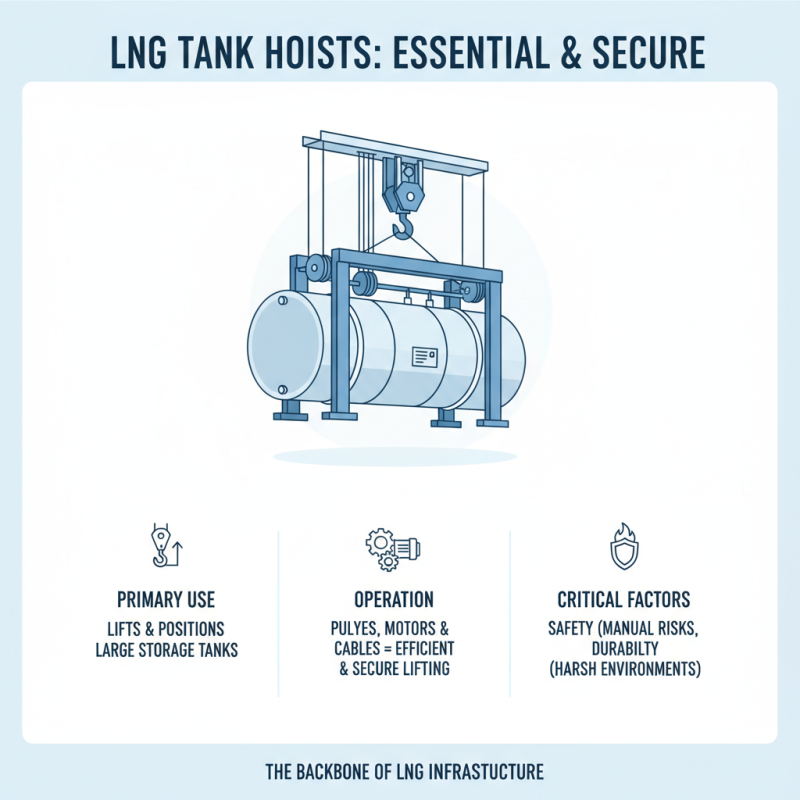

LNG tank hoists are essential equipment in the liquefied natural gas industry. They are primarily used to lift and position large LNG storage tanks safely. These hoists operate using a system of pulleys and motors, making the lifting process both efficient and secure. Their design must endure harsh environmental conditions. Safety is critical when handling LNG, as it poses various risks.

The hoisting process involves multiple stages. Initially, the tank is secured to the hoist. Then, the operator activates the motor, which engages the lifting mechanism. This mechanism typically involves hydraulic systems or electric motors. The tank is slowly raised, allowing for precise positioning. Factors like weather and load weight can complicate this process, requiring careful monitoring.

Operators must be well-trained. They need to understand both the hoist's mechanics and the properties of LNG. Mistakes can lead to severe accidents. Issues may arise during the lift, such as unexpected shifts in weight. Training systems should include simulations to prepare operators for real-life scenarios. The complexity of this work can be daunting, yet it is essential to maintain safety standards and operational efficiency.

LNG tank hoisting systems play a vital role in the storage and transportation of liquefied natural gas. These systems are designed to efficiently lift and position large LNG tanks, enhancing operational safety. The primary components of an LNG tank hoist include the hoist mechanism, support structures, and control systems. Each part must work flawlessly to ensure effective functionality.

The hoist mechanism typically employs hydraulic or electric power for lifting. Hydraulic hoists can exert greater force, which is often necessary for heavy LNG tanks. Support structures, usually composed of robust steel frames, ensure stability during operations. A recent industry report indicated that rigorous testing of these structures is essential for compliance with safety standards. Additionally, control systems include sensors and electronic panels that monitor the hoisting process. Studies show that a failure in the control system can lead to significant safety hazards, highlighting the importance of regular maintenance.

Despite advancements, challenges remain in the design and operation of LNG tank hoist systems. Factors like environmental conditions and equipment wear can affect performance. For example, extreme weather may reduce hoisting speed and efficiency. Operators must therefore conduct thorough inspections to address potential issues. Continuous improvements are needed to optimize these systems while prioritizing safety and operational efficiency.

LNG tank hoists are specialized systems designed to handle the safe transfer and maintenance of liquefied natural gas tanks. These hoists play a crucial role in LNG facilities, ensuring the tanks remain secure during loading and unloading processes. The operational principle relies on a combination of mechanical systems and hydraulic forces. This enables the precise lifting and lowering of tanks with significant weight.

When the hoist is activated, hydraulic pressure generates the needed force. The system moves in a controlled manner, minimizing vibration and ensuring stability. Operators must always monitor the load's weight and balance. An overloaded hoist can lead to safety hazards.

Tip: Regular maintenance of hoist mechanisms is essential. Inspect hydraulic systems regularly to prevent leaks or failures.

Training for operators is equally important. Understanding the hoist's functions leads to safer operations. There may be a learning curve, but diligent practice will improve skills.

Sometimes, decisions made during operation can be flawed. Rushing due to tight schedules may lead to mistakes. It's essential to prioritize safety over speed when dealing with such heavy equipment.

| Feature | Description |

|---|---|

| Hoist Type | Electric/Manual |

| Load Capacity | Up to 300 tons |

| Lifting Speed | 0.5 - 1 m/s |

| Control System | Remote and Manual Control |

| Safety Features | Overload Protection, Emergency Stop |

| Common Applications | LNG storage and transfer |

| Maintenance Frequency | Every 6 months |

| Training Required | Operator Training Certification |

When dealing with LNG tank hoisting, safety is paramount. The process involves lifting large tanks, often filled with liquefied natural gas. Any oversight can lead to catastrophic outcomes. The first line of defense is proper training. Operators must understand the equipment thoroughly. Familiarity with safety protocols is non-negotiable.

Moreover, regular inspection of hoisting equipment is essential. Wear and tear can compromise the integrity of lifts. Minor issues, like frayed cables or worn pulleys, can escalate quickly. It might seem trivial, but these details matter. A moment of negligence can result in significant hazards. Personnel should conduct safety drills. These practices keep everyone prepared for emergencies.

In addition to equipment checks, environmental factors play a role. Wind and weather conditions can affect stability. It’s vital to assess these factors before commencing work. Yet, even the best preparations can't eliminate risks. Operators must always remain vigilant. The unpredictability of the cargo adds another layer of complexity. The LNG state changes with temperature, impacting handling. This makes awareness and adherence to safety measures even more critical.

LNG tank hoists are vital for safe operations in facilities handling liquefied natural gas. Their maintenance requires regular inspections. This ensures safety and efficiency.

Inspect the hoist for wear and tear. Look for any signs of corrosion on the metal components. Lubricate moving parts to prevent sticking. It’s essential to check the cable regularly. Replace any frayed sections immediately.

Tips: Schedule routine inspections. Develop a checklist for your team. Keep records of maintenance activities. This will help you track issues over time.

Monitor the hoist's load capacity closely. Overloading can lead to accidents and costly repairs. Look for any unusual noises during operation. They could signal a problem. It’s easy to overlook details, but this can be dangerous. Regular inspections can save time and money in the long run.