Leave Your Message

A Grain Silo Lift plays a crucial role in modern agriculture. It simplifies the process of moving grain to and from silos. This equipment efficiently reduces manual labor for farmers. By using a Grain Silo Lift, farmers can handle large volumes of grain quickly.

These lifts operate using mechanical systems to elevate or lower grain. They can be powered by electricity or hydraulics. The design often includes an elevator bucket or conveyor system. This ensures the smooth flow of grain, minimizing spillage and delays.

However, the reliance on technology brings challenges. Regular maintenance is essential to avoid breakdowns. Farmers must also stay informed about safety protocols. A malfunction can lead to significant losses. The effectiveness of a Grain Silo Lift depends on both its design and the user’s understanding of its operations.

A grain silo lift is an essential piece of equipment used in the agricultural industry. It assists in transporting grains, such as corn and wheat, from ground level to the top of storage silos. This technology helps optimize the grain handling process, ensuring that farmers can store large quantities efficiently. According to a report from the International Grain Storage Association, up to 30% of harvested crops can be lost without proper storage and handling systems.

Installing and maintaining a grain silo lift involves serious considerations. Many farmers might overlook the importance of regular inspections. Neglecting this can lead to unexpected breakdowns that disrupt operations. Make sure to schedule routine maintenance checks to keep the lift in good condition. If a malfunction occurs, it can result in costly downtime.

Tips: Always ensure the area around the lift is clear. This minimizes the risk of accidents. Additionally, train staff properly on safe operating procedures. Safety should not be an afterthought in daily operations. Remember, keeping the equipment well-maintained can extend its lifespan, despite the initial costs. It’s a delicate balance between investment and efficiency.

Grain silo lifts play a crucial role in modern agriculture. They are designed to efficiently move grain from ground level to the top of a silo. This process is essential for storage and preservation. By elevating grain, these lifts prevent spoilage and help maintain quality.

The importance of grain silo lifts extends beyond mere convenience. They enhance productivity in farming operations. Farmers can store large quantities of grain safely. This safe storage means better profits and reduced waste. However, improper use of these lifts may lead to accidents. Training and regular maintenance are necessary for safety and efficiency.

Grain silo lifts also impact logistics in agriculture. They allow for quick unloading of trucks and fast filling of silos. This efficiency can save time during harvest. Yet, reliance on technology can sometimes create a disconnect with traditional practices. Balancing modern techniques with expert knowledge is vital in every operation.

| Dimension | Description |

|---|---|

| Height | Typically ranges from 30 to 120 feet, depending on storage capacity. |

| Capacity | Can hold between 1,000 to 30,000 bushels of grain. |

| Material | Commonly constructed from galvanized steel or reinforced concrete. |

| Lift Mechanism | Uses an elevator system with buckets or a conveyor to transport grain vertically. |

| Safety Features | Includes emergency stop buttons, safety guards, and monitoring systems. |

| Maintenance | Regular inspections and servicing are necessary to ensure operational efficiency. |

| Importance | Facilitates easy and efficient grain handling, reducing labor costs and time. |

A grain silo lift system is essential for modern agricultural operations. Understanding its key components can significantly enhance efficiency. Typically, these systems involve several critical parts. The grain elevator, for example, functions as the heart of the system. It transports grain to different heights. Industry reports indicate that effective lifting solutions can increase throughput by up to 25%.

The drive system is another crucial element. It powers the lift and ensures smooth operation. Motors vary in size depending on the lift’s capacity. Some systems utilize gear reduction for better torque. A reliable electrical setup is vital. Without it, the entire operation can face delays. Contingency plans should be in place; even minor electrical issues can cripple productivity.

Belt conveyors also play an important role. They help move grain horizontally. While effective, their maintenance often gets overlooked. Regular inspections can prevent significant failures. Data shows that unplanned downtime can cost up to $10,000 per hour in some operations. Addressing wear and tear early can save money and resources. Investing in these technologies is important but understanding their limitations is equally vital.

Grain silo lifts are specialized systems designed to transport grain safely and efficiently. Their operation involves several steps. Initially, grain is funneled into the lift through a series of hoppers. These hoppers can handle large volumes, often exceeding 500 tons per hour. Once inside, the grain is elevated using belts or chains. This vertical movement is crucial for filling silos quickly.

After loading, the lift mechanism engages. A motorized system powers the lift. This movement is controlled by sensors that monitor grain flow. According to a report from the Agricultural Engineering Society, grain lifts improve loading efficiency by up to 30%. Another study indicates that proper maintenance can extend a lift's operational life by 50%.

As the grain reaches the silo's top, it is funneled out smoothly. However, operators must regularly check for clogs. Clogs can cause major disruptions. It's vital to address these issues promptly. Regular maintenance inspections are necessary to ensure optimal functionality. Omitting these checks can lead to expensive repairs. Overall, while these lifts enhance productivity, the importance of diligence in maintenance cannot be overstated.

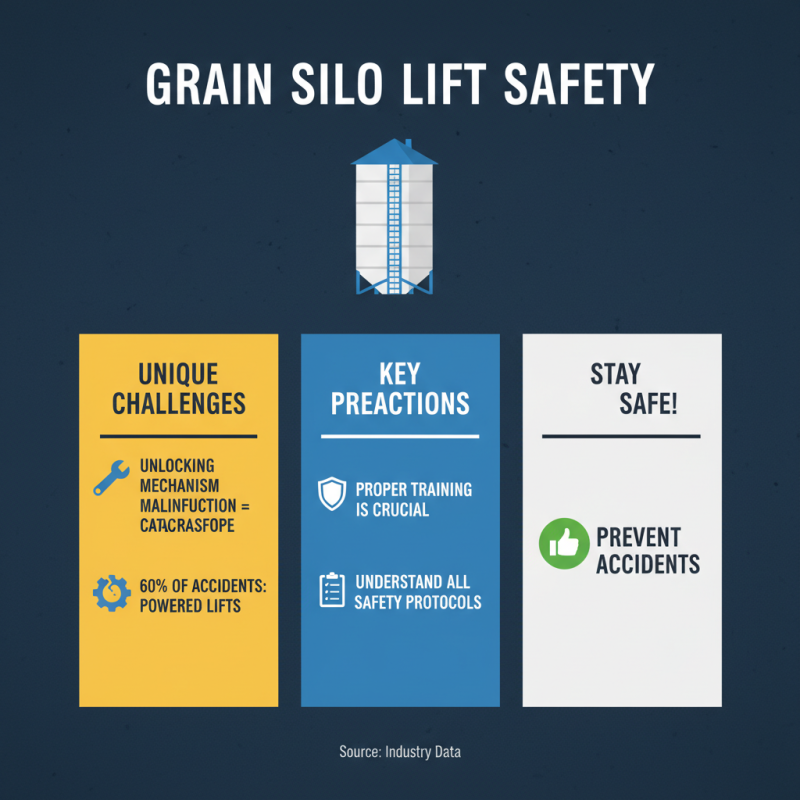

Operating grain silo lifts presents unique safety challenges. The unlocking mechanism must work flawlessly. A malfunction can cause catastrophic failures. According to industry data, about 60% of grain handling accidents involve powered lifts. Proper training is crucial in these situations. Operators need to understand all safety protocols to prevent accidents.

Regular maintenance of equipment cannot be overlooked. A study found that 30% of reported incidents were due to mechanical failures. Daily inspections help identify potential issues. Safety gear should always be worn, including hard hats and harnesses. An unprotected operator facing a height risk is a serious concern. It’s essential to recognize the importance of safety measures.

Lifting loads improperly can lead to dangerous falls. Operators need to gauge the weight of materials accurately. The limits of the lift must be respected. Overloading can result in tipping or equipment damage. An often-overlooked detail is communication. Clear signals among team members can prevent accidents. Effective communication saves lives.