Leave Your Message

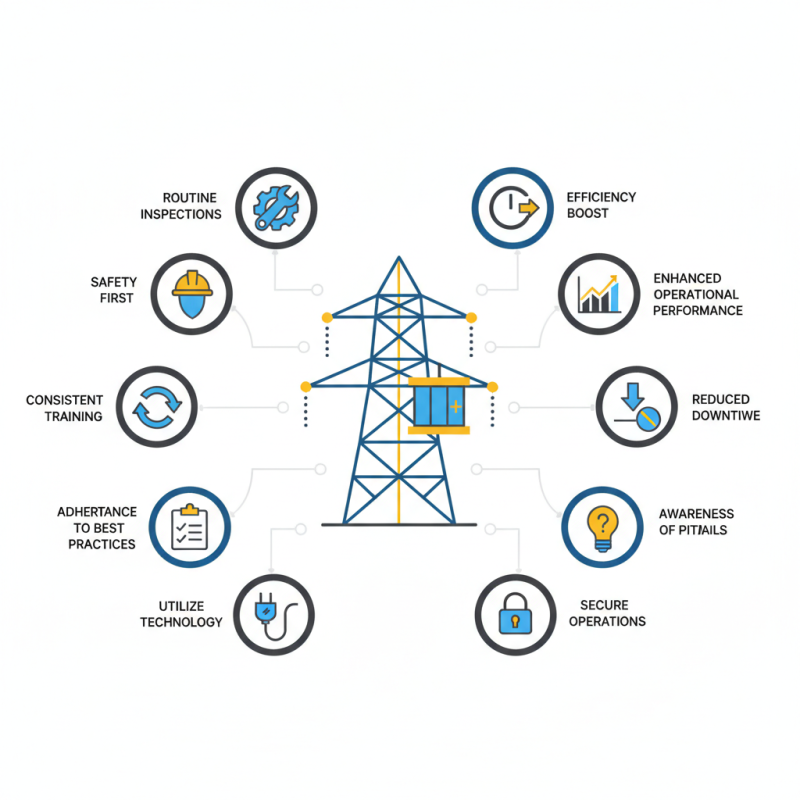

The significance of the Power Grid Tower Elevator cannot be overstated. Recent data from industry reports indicates that effective use of such elevators can enhance operational efficiency by up to 30%. This is crucial for ensuring maintenance tasks are performed safely and swiftly, especially in high-risk environments.

However, many operators overlook essential tips that maximize these benefits. For instance, neglecting routine inspections can result in unexpected failures. According to a study, 15% of accidents stem from improper elevator usage. Such statistics highlight the need for consistent training and adherence to best practices.

Moreover, while technology continues to advance, not every operator fully utilizes these innovations. The gap between potential and actual performance presents an opportunity for reflection. Implementing best practices not only improves safety but also reduces downtime. Power Grid Tower Elevators can transform operations, but only if used effectively and with awareness of their potential pitfalls.

Power grid tower elevators are crucial for maintenance and inspection. These devices facilitate safe access to high structures like transmission towers. Their design ensures workers can reach areas that are otherwise difficult to access. Understanding their operation and features is essential for effective use.

While these elevators enhance safety, user training is often overlooked. Some operators may neglect basic protocols, leading to risky situations. Regular inspections are also vital. Aging equipment may require updates, yet this aspect can be ignored. It’s one area to reflect on constantly. Training sessions should be held frequently, ensuring everyone knows how to operate them correctly.

An effective elevator system isn't just about technology; it's about the people using it. Communication among team members is crucial. Misunderstandings can lead to mistakes. It’s important to foster an environment where feedback is welcomed. Observing how others use the elevators can reveal gaps in the current approach. Regularly assessing safety measures is a must. These elements together form a robust strategy for utilizing power grid tower elevators efficiently.

| Tip No. | Tip Description | Safety Consideration | Maintenance Requirement |

|---|---|---|---|

| 1 | Always conduct a pre-use inspection. | Check for any visible signs of wear or damage. | Weekly inspections required. |

| 2 | Ensure the elevator’s load capacity is respected. | Overloading can lead to severe accidents. | Monthly capacity tests recommended. |

| 3 | Use designated hand signals for communication. | Reduces the risk of miscommunication. | N/A |

| 4 | Keep the area around the elevator clear. | Minimizes hazards during operation. | Daily site checks suggested. |

| 5 | Stay within the designated work zone. | Avoids risky falls or collisions. | Routine zone audits recommended. |

| 6 | Always use personal protective equipment (PPE). | Critical for worker safety. | Regularly check PPE conditions. |

| 7 | Follow the manufacturer's operating instructions. | Ensures proper use of equipment. | Annual training sessions suggested. |

| 8 | Monitor weather conditions during use. | Avoids operations during hazardous weather. | Check forecasts weekly. |

| 9 | Utilize proper lifting techniques. | Prevents injury to workers. | Training every six months recommended. |

| 10 | Keep a maintenance log for the elevator. | Ensures accountability for repairs. | Log updates after each maintenance check. |

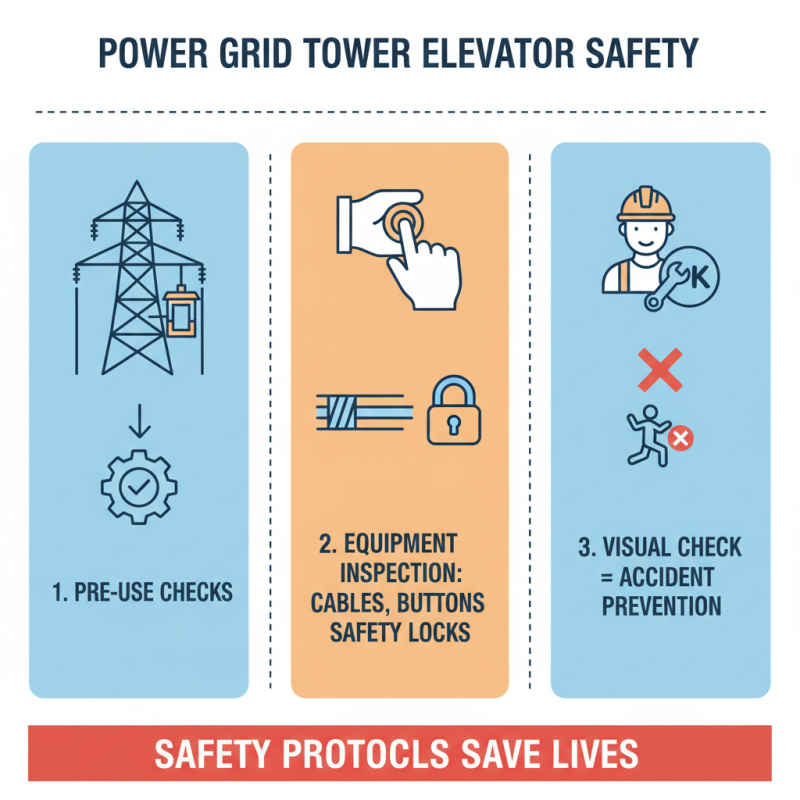

Power grid tower elevators are vital for safe access to high structures. Following safety protocols is crucial. Checking equipment before use is essential. Inspect the cables, buttons, and safety features. A simple visual check can prevent accidents. Some operators forget this step. This oversight can lead to severe consequences, including injuries.

Training is another key aspect. Not all workers receive adequate training. Companies should prioritize thorough instruction on elevator use. Understanding weight limits and emergency procedures is necessary. Clear communication among teams improves safety. Many overlook the importance of discussing roles before beginning work. This lack of coordination can cause delays and, more critically, dangerous situations.

Emergency plans should be rehearsed regularly. Workers should know how to respond to potential failures. Situations may arise that require quick thinking. Familiarity reduces panic. Some teams don’t focus on this regularly. They assume there won't be an issue. In reality, preparation can make a significant difference. Each worker must reflect on their preparedness and mindset.

When operating power grid tower elevators, efficiency is key. One essential tip is proper training for operators. A well-trained operator can navigate challenges quickly, reducing delays. Regular training sessions should include safety protocols and equipment handling. Many operators overlook this aspect, but it’s crucial. Ignoring training can lead to operational mistakes and safety hazards.

Another important practice is routine maintenance. Elevators must be inspected regularly to ensure they function optimally. Preventative checks can help avoid unexpected breakdowns. It may seem tedious, but a broken elevator can halt critical work. Always keep maintenance logs to track repairs. Failure to do so might result in overlooking minor issues that could escalate.

Communication is vital in any operation involving these elevators. Ensure all team members know protocols for signals and alerts. Disorganization often leads to accidents or delays. Consider having a dedicated communication officer during operations. Regularly review communication effectiveness. If issues arise, they hinder overall efficiency and can put staff at risk.

Regular maintenance is crucial for the longevity of power grid tower elevators. Neglecting this aspect can lead to problems. Issues might include unexpected breakdowns or even safety hazards. A simple routine check can prevent major failures.

Inspect the cables, pulleys, and mechanisms regularly. Look for signs of wear and tear. Lubricate moving parts to ensure smooth operation. Keep a log of maintenance activities. This helps in tracking the performance over time. Consider scheduling maintenance during low-usage hours. This minimizes the impact on operations.

Sometimes, maintenance tasks can be overlooked. This is where a good checklist comes in handy. Regular checks can highlight minor issues before they escalate. Evaluate whether your maintenance schedule is effective. Adjust as needed to improve reliability. Proper attention can save time and money in the long run.

The chart above illustrates the frequency of maintenance checks for power grid tower elevators. Regular maintenance, conducted weekly to annually, ensures the longevity and reliability of these vital structures.

Using power grid tower elevators means adhering to strict industry standards and regulations. Compliance ensures safety and efficiency.

Each elevator should have clear signage indicating weight limits and emergency procedures. Regular maintenance checks are crucial.

If inspections are missed, safety can be compromised. Operators need training, but not all facilities prioritize this.

Follow the guidelines set by regulatory bodies. Some operators may overlook minor issues, thinking they won't impact safety. Missing bolts or frayed cables can lead to dangerous situations.

In some areas, outdated practices still persist, leading to compliance failures. It's essential to have a proactive approach to maintain standards. Documenting any issues can help improve future operations.

Incorporating user feedback can enhance safety practices. Many workers hesitate to report problems, fearing repercussions. Creating an open environment for discussion is necessary.

This ensures that every potential issue is addressed. Encourage staff to share their experiences, no matter how small. Continuous improvement should be the goal for all operators.