Leave Your Message

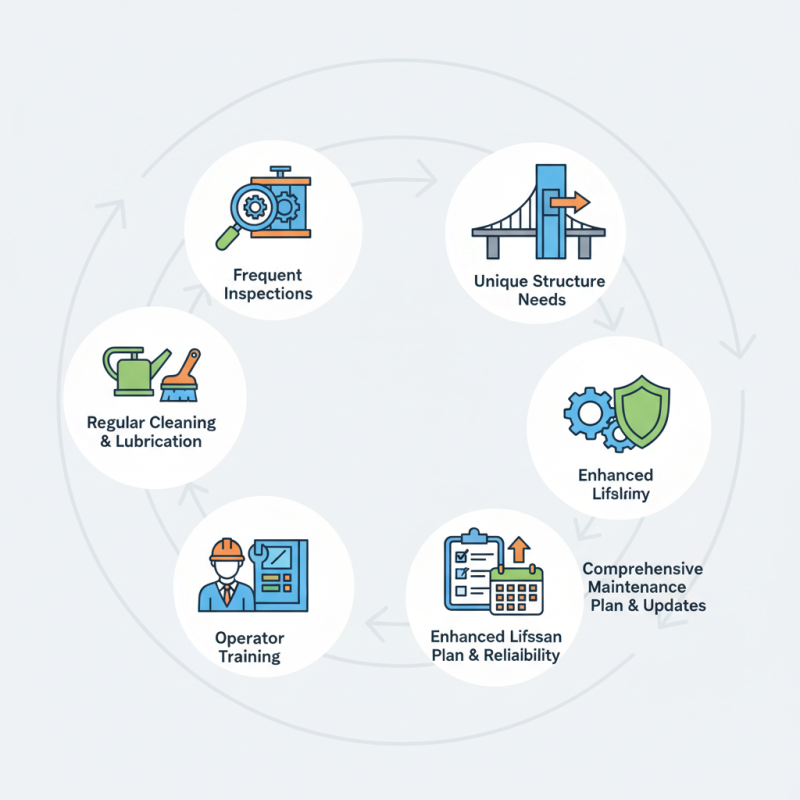

Bridge elevators are crucial for maintaining safety and efficiency in bridge operations. Proper management and upkeep of these systems can significantly enhance their lifespan and reliability. However, many challenges exist in maintaining bridge elevators. Frequent inspections are essential, yet often overlooked. Operators must prioritize training to ensure safe usage and troubleshooting.

Regular cleaning and lubrication are often neglected. Dust and debris can accumulate, causing malfunction. Addressing these issues proactively can prevent larger, costly repairs in the future. Furthermore, understanding the unique needs of each bridge maintenance elevator is vital. Each structure has distinct conditions that may affect the elevator's performance over time.

When maintenance is not comprehensive, operators may encounter unexpected breakdowns. These incidents can disrupt operations and pose safety risks. A solid maintenance plan should include consistent evaluations and updates. Thus, investing in bridge maintenance elevators ultimately pays off in the long run, but it requires commitment and awareness.

Bridge elevators play a crucial role in enhancing the functionality of infrastructure. They facilitate the clean transition between different levels, particularly in locations where space is limited. Understanding their core components is essential for effective maintenance. Key parts include the lift mechanism, control systems, and the safety gear. Each component must work in perfect harmony to ensure safety and efficiency.

Maintenance professionals frequently report that neglect of these systems can lead to failures. For instance, according to a recent industry analysis, 30% of bridge elevator failures stem from inadequate inspections. Regular assessments of each component are vital. This can prevent costly repairs and ensure smooth operation.

Tip: Create a maintenance schedule. Regular checks can catch issues early. Inspect cables, pulleys, and hydraulic fluids monthly.

Moreover, understanding the functions of bridge elevators allows for better troubleshooting. If an elevator does not respond, it might indicate problems in the control system. A clear understanding of how each part works helps in diagnosing these problems accurately.

Tip: Keep a log of all repairs. Tracking patterns can reveal recurring issues.

Investing time in understanding bridge elevators pays off. However, challenges exist. Not all staff may be trained on the complexities of these systems. This can lead to oversight in maintenance protocols.

Regular inspection is critical for effective bridge elevator maintenance. It ensures that all components function correctly and safely. Inspecting the mechanical parts helps identify wear and tear that could lead to failures. Regular checks should include the cables, pulleys, and motors. These elements are essential for smooth operation. Ignoring these aspects could result in costly repairs or accidents.

During inspections, it’s important to look for unusual sounds or vibrations. Such signs often indicate potential problems. Small issues can escalate if not addressed promptly. Schedule inspections at regular intervals to ensure consistent performance. However, even well-maintained elevators can face unexpected breakdowns. It’s essential to have a responsive repair team ready to tackle emergencies.

Many bridge elevator operators overlook minor details. They may skip inspections due to time constraints or budget limitations. This practice can lead to bigger challenges later on. Instead of focusing solely on costs, consider the long-term benefits of regular inspections. Implementing a solid maintenance plan ultimately saves time and resources. Investing in routine checks yields safety and efficiency.

Bridge elevators are crucial for moving people and goods. However, they can face various problems. Regular inspections can help identify issues early. Common problems include mechanical failures, oil leaks, or misalignment. Each of these can lead to serious safety hazards.

In addition to mechanical issues, electrical faults can arise. Wiring problems often lead to sudden stops or failure to operate. Regular maintenance can prevent these surprises. Ensure that emergency systems are functional. Sometimes, user errors can also be a cause of malfunctions.

Operators should be trained adequately. They often overlook simple checks. These small actions can prevent bigger issues later. Keeping a detailed log of elevator performance can reveal patterns. Regular reflections on maintenance practices are necessary for improving efficiency.

Bridge elevators require regular care to function efficiently. Cleaning and lubrication are two essential maintenance practices. The cleanliness of components can impact overall performance. Dust and grime may accumulate over time. This buildup can lead to malfunctions or slow operations.

Tips: Regularly inspect the elevator for visible dirt. Use appropriate cleaning agents that won't damage surfaces.

Lubricating moving parts is equally important. Proper lubrication prevents wear and tear. It ensures smooth operation and prolongs the life of the elevator. However, over-lubricating can attract dust and dirt. Finding the right balance is crucial.

Tips: Use high-quality lubricants and apply them sparingly. Follow manufacturer recommendations for lubrication intervals. Regularly check for signs of rust or corrosion.

Inconsistent maintenance efforts can lead to costly repairs. Recognizing areas that need improvement is vital. Regular reviews of cleaning methods can enhance efficiency. Being proactive is key.

Establishing a maintenance schedule for bridge elevators is crucial. Regular checks on the mechanical components prevent unexpected failures. These elevators work in demanding environments, often exposed to weather changes. A maintenance log should track inspections, repairs, and adjustments.

Routine inspections should happen monthly. During each visit, check the cables for signs of wear. Lubricate moving parts to ensure smooth operation. Look out for unusual noises; they may indicate a problem. It’s essential to involve qualified personnel for thorough assessments.

While planned maintenance helps, it is not foolproof. Some issues may arise unexpectedly. Technicians should be prepared for emergencies. Reflecting on past incidents can help improve future protocols. Awareness of potential risks is key to long-term performance.