Leave Your Message

Cement Plants Lift are crucial in the construction industry. They enhance productivity by efficiently moving materials. Dr. Jane Smith, a renowned expert in structural engineering, states, “The effectiveness of Cement Plants Lift can transform project timelines.” This highlights their importance.

These systems improve safety and reduce labor costs. However, they require regular maintenance and skilled operators. Any failures can halt a project and increase expenses. The benefits are clear, yet there are challenges that need careful consideration.

As industries evolve, so does the technology behind Cement Plants Lift. This innovation is not without flaws. Continuous improvement is essential for optimizing operations. Ensuring safety and efficiency remains a collective responsibility.

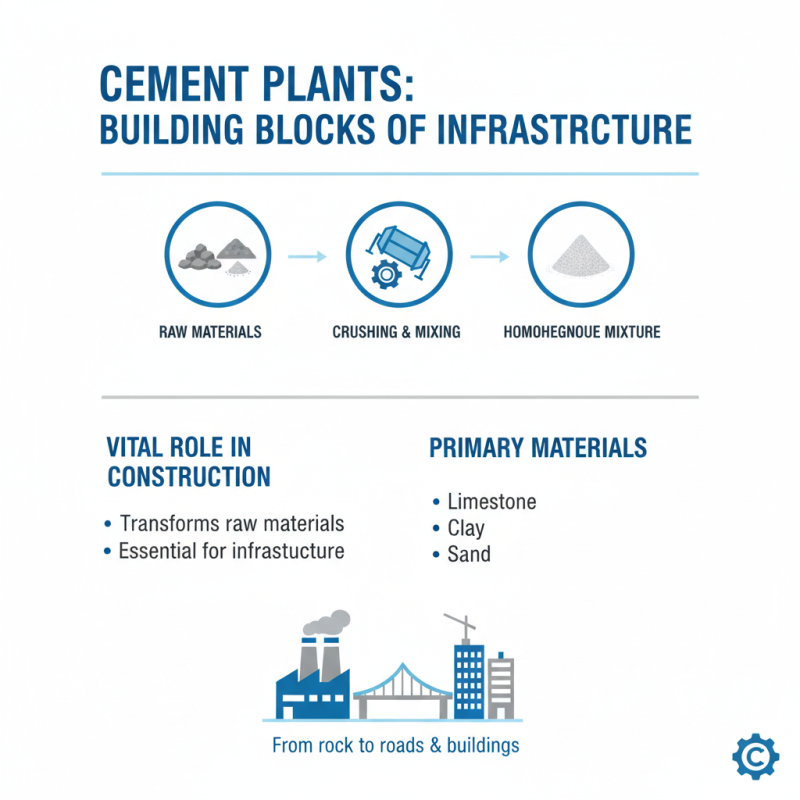

Cement plants play a vital role in construction. They transform raw materials into essential building blocks for infrastructure. The primary materials include limestone, clay, and sand. These are crushed and mixed to create a homogeneous mixture.

The production process requires high temperatures. In kilns, materials can reach up to 1,500 degrees Celsius. This intense heat causes chemical reactions. These reactions lead to the formation of clinker, which is then ground into fine powder. The dust we see is cement, a cornerstone of modern construction.

While cement plants offer benefits, they have drawbacks. Emissions from these facilities can affect air quality. Dust and pollutants may lead to health issues. Furthermore, the extensive use of resources raises concerns about sustainability. We must reflect on these impacts as construction demand grows. Exploring eco-friendly practices could be a solution for the future.

Cement production is a complex process. It involves several key components working together. These components include raw material extraction, crushing, and blending. The integration of these elements is crucial for creating high-quality cement.

During the raw material extraction phase, limestone and clay are gathered. Afterward, they undergo crushing to achieve smaller particle sizes. Blending these materials ensures a uniform composition. The next step is heating in a kiln, where temperatures can exceed 1400°C. This process transforms the raw materials into clinker, a critical ingredient in cement.

Tips: Monitor the moisture levels of raw materials. Too much moisture can affect quality. Ensure proper maintenance of equipment. Downtime can lead to increased costs.

After cooling, the clinker is ground with gypsum. This gives cement its characteristic strength and consistency. While the integration of components is essential, errors in any stage can lead to defects. For example, an uneven blend may result in weak cement batches. The importance of careful monitoring cannot be overstated.

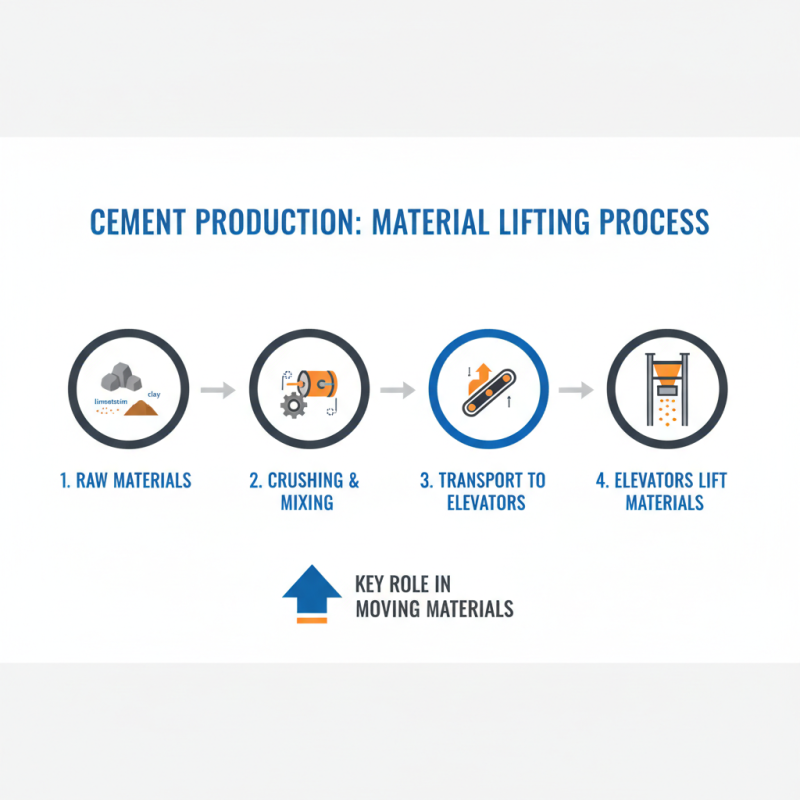

Cement plants rely on a complex mechanism to lift and transport materials during production. The lifting process begins with raw materials. These materials, including limestone and clay, are crushed and mixed. This mixture is then transported to elevators. These elevators play a key role in moving materials to various stages.

Inside the plant, the lifting mechanisms utilize buckets or conveyor belts. These systems are crucial in maintaining efficiency. They reduce manual labor and minimize the risk of contamination. However, the reliability of these systems is sometimes questionable. Mechanical failures can hinder production and increase costs.

To optimize this process, regular maintenance is essential. Operators must ensure the equipment is in good condition. Monitoring performance can prevent unexpected breakdowns. Despite the advanced technology in lifting, human oversight remains vital. Mistakes in operations can lead to significant delays and resource loss. Therefore, continuous training for workers is equally important.

Cement plants play a crucial role in construction and infrastructure development. They produce cement, a key ingredient in concrete. Concrete is widely used in buildings, roads, bridges, and more. The reliable supply of quality cement supports large-scale projects. This is vital for urban development and improving living standards.

One significant advantage of cement plants is their ability to create jobs. They employ a diverse workforce, from engineers to laborers. This employment boosts local economies, providing livelihoods for many families. Additionally, cement production can impact the environment. Plants often strive to implement eco-friendly practices, reducing their carbon footprint while meeting demands.

Cement plants also face challenges. The production process can generate significant emissions. Sustainability remains a pressing concern. While advancements are made, ongoing reflection is necessary. Continuous improvement is key to balancing industrial growth and environmental stewardship. In this way, cement plants can better serve communities and contribute positively to development.

Cement production has significant environmental implications. The process releases considerable carbon emissions. This is a major concern for sustainability efforts. Many industries are now looking for innovative ways to minimize their carbon footprints. New technologies are being developed to combat these issues.

One such innovation is the use of alternative fuels. These fuels can replace traditional fossil fuels in the cement-making process. By utilizing waste materials, industries can reduce their impact. However, this approach still needs careful assessment. Not all waste is suitable for cement production. The quality must be ensured to avoid compromising the final product.

Another focus is carbon capture technology. This method involves capturing and storing carbon emissions produced during cement manufacturing. While promising, it is still in its early stages. The high costs and technical challenges present hurdles. Stakeholders must weigh the potential benefits against these obstacles. Further research and development are crucial for widespread adoption.