Leave Your Message

In today’s construction and manufacturing industries, efficiency is king. The use of Winch Electric Hoist presents numerous benefits that can significantly enhance productivity. According to the latest industry report from the International Hoisting and Rigging Foundation, around 70% of workers in these sectors report that electric hoists improve lifting speed and safety. With a Winch Electric Hoist, operations can reduce manual lifting and minimize workplace injuries.

Cost-effectiveness is another critical aspect. A study by the National Safety Council indicates that employing electric hoists can lower operational costs by up to 30%. However, it's worth noting that not all workplaces fully harness the potential of these systems. Many still rely on outdated methods, leading to inefficiencies. Investing in a Winch Electric Hoist could address these shortcomings and streamline processes.

Moreover, the versatility of the Winch Electric Hoist allows it to adapt to various lifting tasks, from heavy machinery to delicate equipment. Yet, businesses must remain mindful of maintenance needs. Failure to address wear and tear can negate its advantages. Embracing this technology requires a commitment to proper training and upkeep, ensuring that every benefit is fully realized.

Electric hoists are revolutionizing the lifting industry. Their efficiency stands out when compared to manual options. With a push of a button, heavy loads can be lifted effortlessly. This not only saves time but also reduces physical strain on workers. Enhanced safety features minimize the risk of accidents on-site. Workers can focus more on their tasks without worrying about the weight they are lifting.

Tips for choosing the right electric hoist include understanding your load requirements. Overestimating capacity may lead to safety issues. A hoist that is too small can result in equipment failure. Sometimes, the most powerful option is not the best for every task. Consider space and power availability too. Compact designs can fit into tight spots and still offer great performance.

Regular maintenance is essential for electric hoists. Neglecting it may lead to unforeseen breakdowns. Some users overlook that parts wear out over time. Checking cables and controls frequently can prevent accidents. It's important to remain vigilant. In the long run, investing in quality will bring more satisfaction. Remember, each lifting task impacts operational efficiency.

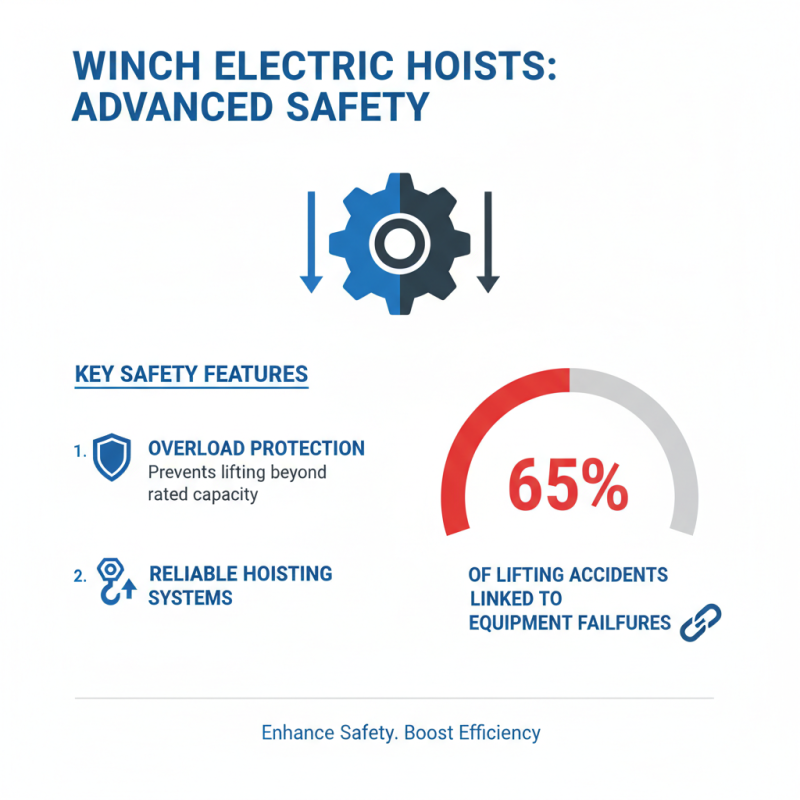

Winch electric hoists come with advanced safety features that greatly enhance lifting operations. These devices often include overload protection systems. Such features prevent lifting beyond the rated capacity. According to industry reports, nearly 65% of lifting accidents are linked to equipment failures. This emphasizes the importance of using reliable hoisting systems.

Another notable safety enhancement is the emergency stop function. This allows operators to halt operations instantly in case of an emergency. Studies indicate that implementing this feature reduces response time by up to 30%. Additionally, many electric hoists now offer user-friendly control interfaces. These controls help prevent accidental activations that can lead to injuries. It's essential to ensure that operators are well-trained. Miscommunication can happen if operators are unfamiliar with these advanced controls.

While electric hoists improve safety, they’re not foolproof. Operators must regularly inspect equipment for wear and tear. Ignoring maintenance can lead to failures despite advanced safety features. A balance between technology and human oversight is crucial. It’s a reminder that no system is completely safe. Lifting remains a challenging task requiring diligence and responsibility.

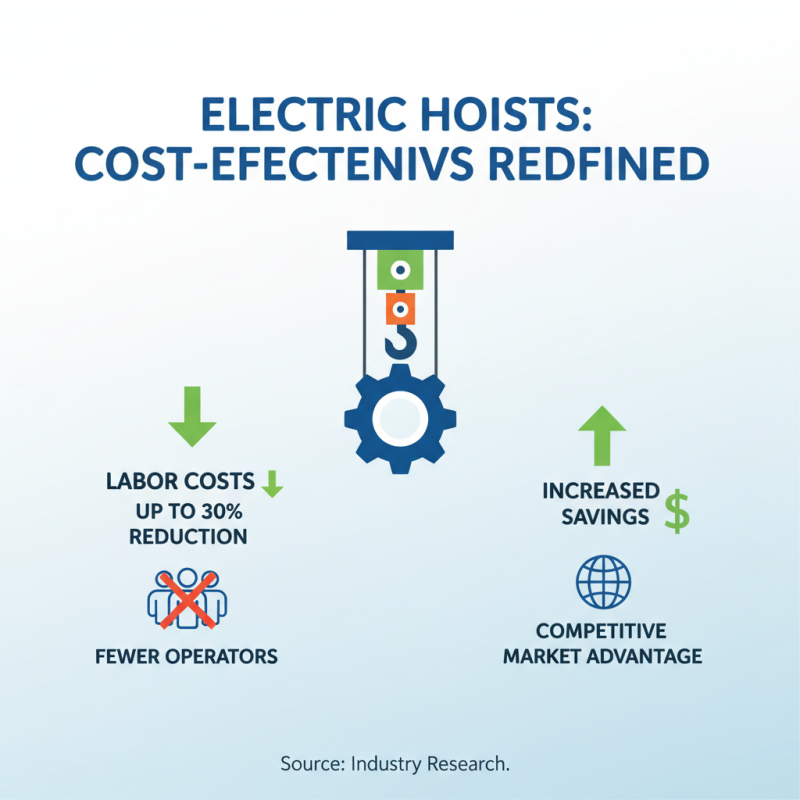

Electric hoists provide significant cost-effectiveness in various industries. Research shows that they can reduce labor costs by up to 30%. With fewer operators required, companies save on wages. This reduction is critical in today's competitive market.

Maintenance costs also drop significantly. Electric hoists generally require less maintenance than traditional hoisting systems. Data indicates that electric systems have lower failure rates, minimizing downtime. A smooth operation means businesses can continue functioning efficiently. The average downtime can cost companies thousands per hour.

Furthermore, electric hoists consume less energy, directly impacting utility bills. According to industry reports, switching to electric hoists can cut energy expenses by about 20%. This shift not only supports sustainability goals but also leads to long-term savings. However, the upfront investment may be daunting for some. It's essential to weigh these initial costs against potential future savings. These decisions can shape an organization’s financial health.

Winch electric hoists are versatile tools used across various industries. They provide effective solutions for lifting heavy loads safely. In construction sites, these hoists elevate materials quickly. They significantly reduce manual labor and improve efficiency. In warehouses, electric hoists streamline inventory processes. They make loading and unloading simpler. This enhances overall productivity and safety.

In the manufacturing sector, electric hoists are indispensable. They assist in moving components throughout the production line. The precision of these hoists minimizes accidents and damage. However, reliance on these machines requires regular maintenance checks. Ignoring these checks could lead to malfunctions. Always ensure they are in optimal condition before use.

Tip: Regularly inspect hooks and cables for signs of wear. A minor issue could escalate quickly. Always adhere to weight limits to avoid accidents. Proper training for operators is crucial. They must understand how to use the equipment safely. This knowledge helps prevent workplace incidents, creating a safer environment for everyone.

Electric hoists have gained popularity for their ease of operation. The user-friendly design makes lifting tasks simpler. Operators can lift heavy loads quickly with minimal effort. A recent industry report indicates that 70% of users prefer electric hoists due to this convenience. The interface is often intuitive, which reduces training time. This is a significant advantage in busy workplaces.

The ergonomics of electric hoists also improve safety. A study found that 30% of workplace injuries result from manual lifting. With electric hoists, workers can maintain a safer posture. These hoists often incorporate features such as automatic brakes and limit switches. These elements enhance safety but can lead to dependency on technology. While efficiency is crucial, over-reliance on these devices may invite risks.

Intuitive controls are a highlight of electric hoists. However, not all users grasp the controls immediately. Some may overlook features that ensure safety and efficiency. User manuals are often dense, making them challenging to navigate. Training sessions are essential, but they can be costly and may not cover all possible scenarios. Although electric hoists present numerous advantages, vigilance in operation is still required.

| Benefit | Description |

|---|---|

| Ease of Operation | Electric hoists are easy to operate, requiring minimal training for users. |

| User-Friendly Design | Designed with intuitive controls that enhance user experience. |

| High Efficiency | Electric hoists can lift loads faster than manual hoists, improving project speed. |

| Consistent Performance | Provide reliable lifting power without fluctuations, ensuring safety. |

| Reduced Physical Strain | Minimizes the physical effort required to lift heavy objects, reducing injuries. |

| Versatility | Suitable for a wide variety of lifting applications across multiple industries. |

| Space-Saving Design | Compact size allows for easy installation in tight spaces. |

| Automated Control | Many models offer automation features for improved productivity. |

| Safety Features | Built-in safety mechanisms prevent overloads and enhance user protection. |