3S LIFT Horizontal Lifeline System

Video

product description

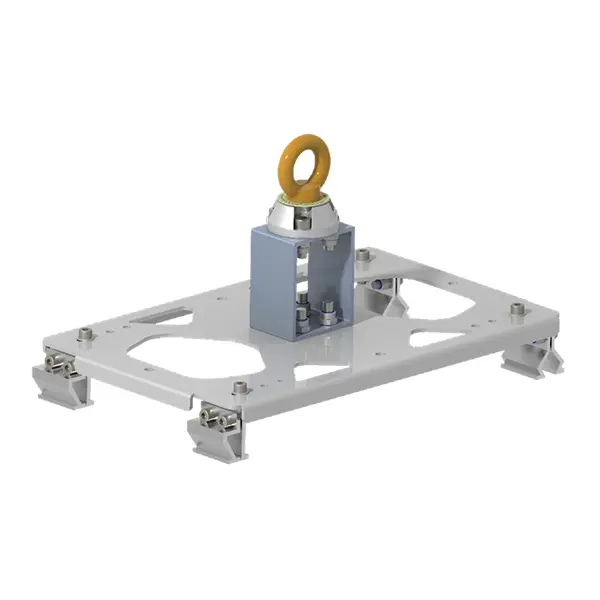

End anchor

The end anchor consists primarily of an anchor point and a bracket, both fabricated from stainless steel 316L. This material choice ensures high corrosion resistance, making it suitable for use in various environments. The end anchor has successfully obtained CE certification, demonstrating its compliance with the EN 795: 2012 standard. This certification validates that the end anchor meets the necessary safety and quality requirements for use in fall - protection systems, providing users with reliable and certified components for ensuring worker safety at height.

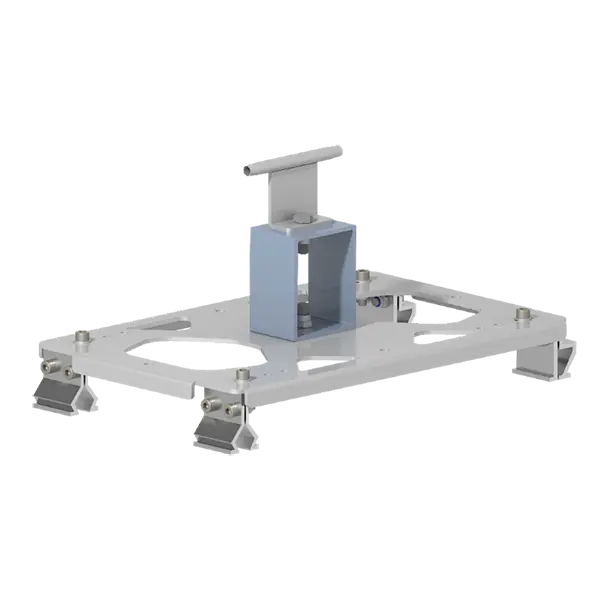

Intermediate anchor

The intermediate anchor is designed as a welded member. One of its key advantages is that it does not require removal. This is because the traveller can glide through it seamlessly, allowing for unhindered movement within the relevant system. This design feature streamlines operations and eliminates the need for any time - consuming or potentially hazardous procedures related to anchor removal and reinstallation.

Turn anchor kits

The turn anchor kits are installed to enable the wire rope to navigate around a corner. Constructed as welded members, these kits offer the convenience of remaining in place permanently. This is due to the fact that a traveller can smoothly pass through them, ensuring uninterrupted movement along the wire rope system. Their fixed - in - place design eliminates the need for any removal or reinstallation procedures, which could be both time - consuming and potentially risky. This not only simplifies the operation of the wire rope system but also enhances its overall safety and reliability.

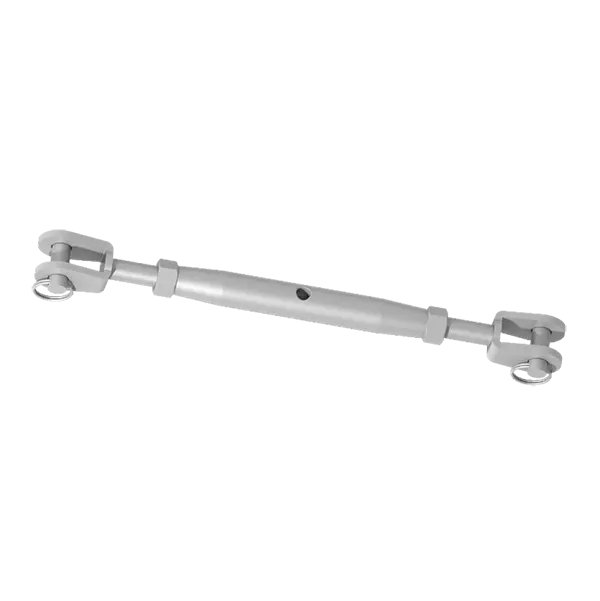

Tensioner

The tensioner serves a dual - purpose function within the horizontal lifeline system. Firstly, it is utilized to tension the lifeline, ensuring that it is taut and ready to perform its safety - critical role. Secondly, in the unfortunate event of a person falling, the tensioner helps to minimize the lateral displacement of the lifeline. By reducing this lateral movement, it effectively decreases the falling height of the individual. This, in turn, significantly lessens the impact force experienced during the fall. In essence, the tensioner plays a crucial part in enhancing the overall safety and performance of the horizontal lifeline system, providing a more reliable safeguard for workers operating at height.

Shock absorber

The shock absorber serves as a crucial buffer within the fall - protection system. When a fall occurs, it actively reduces the impact force generated. By effectively dissipating this energy, the shock absorber significantly contributes to ensuring the safety of personnel. To a notable degree, it mitigates the potential for impact - related injuries, acting as a key safeguard in high - risk, elevated work environments. Its function is integral to minimizing the severity of harm that could otherwise result from a fall, thus enhancing overall safety for those using the fall - protection equipment.

Traveller

The traveller is designed to glide effortlessly along the lifeline. It can smoothly traverse both the intermediate anchor and the turn anchor kits without any hindrance. Moreover, it offers great flexibility as it can be assembled or disassembled at any point along the length of the lifeline. This allows for easy adjustment and customization based on the specific requirements of the work at hand, whether it involves changing the location of the traveller during different stages of a project or adapting to various configurations of the lifeline system in different work environments.

Wire rope

The wire rope has a diameter of 8 mm and is available in three material options: zinc - coated, stainless steel 304, and stainless steel 316. Each material offers distinct properties. The zinc - coated wire rope provides a certain level of corrosion resistance at a potentially more cost - effective price point. Stainless steel 304 is known for its good general corrosion resistance and mechanical properties, making it suitable for a wide range of applications. Stainless steel 316, on the other hand, offers enhanced resistance to corrosion, especially in more aggressive environments such as those with high salt content or chemical exposure, ensuring durability and reliability in challenging conditions.

Specifications

Model |

TF-SH80/TF-SH83/TF-SH10 |

Material |

Stainless steel / hot-dip galvanizing wire rope |

Wire rope diameter |

8.0 mm/8.3 mm/9.5 mm |

Rated load |

12 kN |

The distance between two adjacent end anchors |

≤ 12 m. |

Applicable fall arrester type |

TF-H10 |

Standard |

EN 795 |

Certified by |

CE |

Customization |

Customized design and manufacture according to the customer’s demands. |

Applications

Ms.Lily International Sales Director

Ms.Lily International Sales Director Join 3S Group

Join 3S Group